In recent years, with the development of the social economy and the improvement of urban appearance, stone curtain walls are favored by the majority of owners and architects in the exterior decoration of buildings, and have accounted for a considerable proportion of existing buildings. Moreover, the height of the stone curtain wall application is getting higher and higher, and the volume is getting bigger and bigger;

More and more varieties of stone are used, from the original single granite to Daliite, limestone, sandstone, and other varieties; The shape is becoming more and more complex, the requirements for installation and construction technology are becoming more and more stringent, and the requirements for safety are getting higher and higher.

However, the domestic stone curtain wall material market is chaotic, the construction unit production technology lacks technical specifications, and the technical quality of construction personnel is low, which brings great safety risks to the project. Due to various reasons, the selection of stone plates, dry hanging glue, dry hanging parts, and the production and installation of pre-(post)embedded parts are the most easily overlooked, and a brief analysis of how the four materials should be selected.

1. Stone slab

As the stone curtain wall of the outer envelope structure, it does not bear the load of the main structure, but it is on the outer surface of the building, in addition to bearing its own weight, it also bears the influence of wind load and seismic action and temperature change, so the stone must be safe and reliable. The performance and quality requirements for the stone include compressive strength, flexural strength, flexural strength, hardness, wear resistance, frost resistance, fire resistance, processability, etc.

The stone selected for the stone curtain wall is naturally formed, natural stone is mined from the mountain, and its importance depends on the mineral composition and structure, but in the above series of properties tested by sampling, each sample is different, not as small as industrial products. Due to the different material surfaces, the measured performance will not be exactly the same.

Based on the above situation, when the architect determines the stone variety, he must be cautious in the use of stone slabs, and must do the following work:

1. Do a good job in basic material property test: its compressive strength, flexural strength, bending strength, hardness, wear resistance, frost resistance, fire resistance, processability, etc. must meet the specifications and design requirements, and at the same time the stone slab used for the curtain wall, each batch should be subjected to bending strength test. For use in areas where negative temperatures may occur, freeze-thaw tests are also required. It can only be used if the performance indicators meet the design and specification requirements.

2. Control the processing accuracy of the stone to avoid secondary cutting at the construction site. Affected by the installation process, the stone dry hanging process now commonly used needs to punch holes or grooves on the section of the stone plate, so the thickness of the stone is limited by the installation process, and a structural thickness must be guaranteed, so pay special attention to the thickness of the plate when the process acceptance of the stone plate, the allowable deviation is +2 mm, the negative difference is not allowed, and it is to be checked block by block.

3. Avoid damage during mining, transportation, cutting, and installation, once the stone has been collided, the damage, especially internal injuries, is difficult to be checked, but it will develop over time, and serious will break, thus bringing safety hazards. In the process of processing, transportation, and installation of stone, it should be strictly checked.

4. Do a good job in the protective treatment of the stone surface to ensure the dryness of the inside of the stone and ensure that the natural properties of the stone remain unchanged.

5. The area of a single piece of stone should not be too large, and the “Technical Specifications for Metal and Stone Curtain Wall Engineering” stipulates that it should not exceed 1.5 square meters.

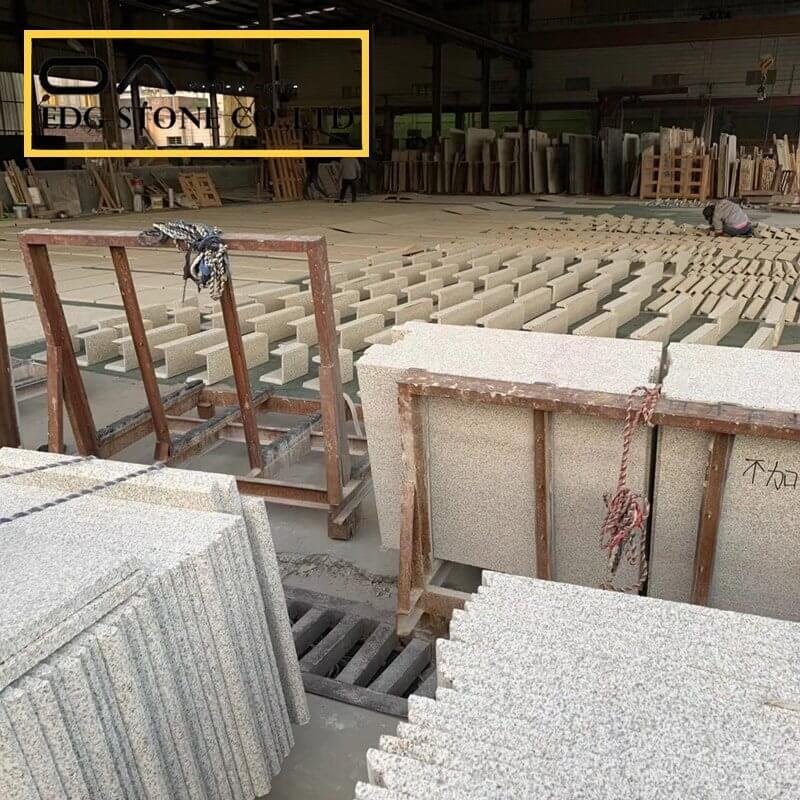

6. Stacking of stones:

(1) Stacked in the specified site according to the specifications of the plate;

(2) It is strictly forbidden to mix with corrosive materials. Eliminate contact with acids and alkalis;

(3) Indicate the product processing sequence number, pay attention to no collision, pollution, etc. Padding 100 mm at the bottom of the plate with a long permeable material and ensuring its smoothness.

2. stone dry hanging glue

The load borne by the stone curtain wall panel is transmitted to the pendant through the glue between the stone and the pendant, and then transmitted from the pendant to the support structure, so the stone curtain wall dry hanging glue must be structural glue, and the dry hanging glue must not only have good adhesion with the stone, but also have good adhesion with the pendant (the material of the pendant can be stainless steel or aluminum alloy), and the rubber layer itself must also have suitable strength, good toughness and elasticity.

This point is stipulated in the “Metal and Stone Curtain Wall Engineering Technical Specification” (JGJ133-2001) as follows: the stone slab and stainless steel pendant should be bonded with epoxy resin-type stone special structural adhesive. The State Economic and Trade Commission issued the “Epoxy Adhesive for Dry-hanging Stone Curtain Wall” (JC887-2001) in December 2001, which was implemented on June 1, 2002, according to the characteristics of the stone curtain wall, 6 mandatory indicators were stipulated, and this regulation was also issued for more than 5 years, but no structural adhesive was used in some projects, and no epoxy resin type stone special structural adhesive was used. At present, the common use is still Hercules glue, Hercules glue is the stone and stone bonding glue, it is unscientific to use it for the bonding of stone and metal, its toughness, elasticity, and bonding strength are weaker than the stone dry hanging glue many times, and when the metal rust is easy to penetrate and corrode the stone.

Although some also advertise and advertise that can be used for stone curtain walls, in fact, these glues cannot be used for stone curtain walls. On the basis of the implementation of the “Metal and Stone Curtain Wall Engineering Technical Specification” (JGJ133-2001), the selection of the correct stone curtain wall dry hanging glue is the current top priority to ensure the safety of the stone curtain wall!

On the basis of the correct selection of stone dry hanging glue, it is also necessary to carry out the compatibility and adhesion test of dry hanging adhesive, and it can be used in the project only after the test is qualified. How to use dry hanging adhesive reasonably during the construction process is also very important, and the following points need to be paid attention to:

1. The preparation and coating of stone opening pendant groove, dry hanging glue, and dry pendant fixing should be carried out directly in the processing workshop; Stone grooving must be machined, strengthen grooving process control and processing inspection, to avoid damage to the stone.

2. The pasting surface should be dry and non-wet (humidity is not higher than 15%), dust-free, clean, rough, and oil-free.

3. The physical and mechanical properties of dry hanging rubber are directly related to the thickness of the glue (generally 1 mm ~ 2 mm), the processing of dry hanging groove and dry hanging groove should be strict to ensure the processing size and accuracy, and the cooperation of dry hanging rubber and dry hanging groove should be strict to ensure the thickness and depth of dry hanging glue.

4. Since the strength of the stone dry hanging glue is related to the curing time and curing temperature, it is necessary to ensure that there is enough curing and curing time, and it cannot be moved or loaded in the early stage of curing.

3. stone dry pendants

The stone dry pendant hangs dozens of kilograms of stone high on the wall, but its quality makes people worry.

In previous years, the Ministry of Foreign Affairs building, the Capital Airport terminal, etc. have had incidents of slates falling from the sky and smashing cars and other items, which has caused a certain impact at home and abroad, the cause of the incident is that the pendant is of poor quality, the weld of the welding head is not full, and the pendant falls off due to oxidation and fracture after high-temperature annealing. Nowadays, due to price factors, the dry pendant products market is more chaotic, the market sales, engineering products are national standard stainless steel, there are 7075 aluminum silicon magnesium alloy, there is galvanized sheet, and stainless iron, the quality of the above products is uneven, this can also be reflected from its tensile strength, national standard stainless steel 530Mpa ~ 620Mpa, national standard aluminum alloy 540Mpa ~ 560Mpa, stainless iron 160Mpa ~ 180Mpa. Obviously, the tensile strength of stainless iron is not up to 1/3 of the strength of stainless steel, and it is inappropriate to use it as a dry pendant, and its danger is indeed too great.

Therefore, the material selection of dry pendants must be cautious, the performance indicators of dry pendants must meet the design and specification requirements, and do a good job of testing during construction, and at the same time try to select castings, so as to avoid affecting safety due to welding quality.

4. Pre-(post)embedded parts

The structural system of the stone curtain wall is ultimately connected to the main structure through pre- (post)embedded parts, and the quality of pre-(post)embedded parts is particularly important. In order to ensure the quality of pre-(post)embedded parts, the following points should be paid attention to in the construction of stone curtain wall:

1. The pre-(post)embedded parts must be strictly calculated by the designer according to the force situation to determine the specifications of the anchor plate, the diameter of the anchor bar, the length and the thickness of the weld, etc., among which the minimum thickness of the anchor plate and the spacing of the anchor bar, the distance from the anchor bar to the edge of the anchor plate, etc. must also meet the structural requirements of the specification.

2. The pre-(post)embedded parts shall not be set on the lightweight partition wall. The reliable connection point between the curtain wall embedded parts and the main structure of the building is mainly in the column and beam plates of the reinforced concrete (or steel structure) of the main structure. For floors with large floor heights, in order to solve the force problem of curtain wall poles, in addition to increasing the cross-section size of the pole or using high-strength materials, some projects add a support point on the wall between the upper and lower floor beams, which should be reliable and effective on the reinforced mixed soil (or steel structure) structural beam (column). In fact, in the “Curtain Wall Code”, there is already a provision that “lightweight infill wall should not be used as a supporting structure of the curtain wall”.

3. The welding quality of embedded parts should be paid attention to. The common form of embedded parts is composed of anchor plate welding anchor bars, The anchor plates are usually made of Q235 high-quality carbon steel plates, and the anchor bars should also try to use first-class steel bars with better welding performance. The welding method is best to use bevel plug welding so that the quality is more reliable. The welding quality of the anchor plate and anchor bar is the key to the quality of the embedded parts. To ensure the quality of the weld, the welding operator must be trained and licensed, but due to the different responsibilities of the welder, the quality of the embedded iron weld must also be strictly inspected and accepted.

4. It is essential for the pull-out test of embedded parts. Due to the fact that the curtain wall project is not pre-embedded, embedded failure remediation, or old building modification, post-embedded parts are often used to solve the connection problem between the curtain wall components and the building structure. During the inspection, regardless of whether the connection is reliable or not, the on-site pull-out test is used to determine its bearing capacity. At present, the quality hidden dangers of post-anchor construction are the reasons for construction operations, such as drilling often encounters steel bars, resulting in insufficient or partial reinforcement depth, and unclean cleaning of hole dust and debris; Second, the anchoring matrix is unreal and unreliable, such as insufficient strength of the concrete substrate and insufficient margin, which will lead to the cracking of the concrete substrate and cause anchorage failure. Therefore, on-site construction management personnel should seriously carry out technical disclosure, strengthen quality inspection, and random sampling of on-site pull-out tests should be carried out, and must not be fake or perfunctory.

5. The quality of chemical anchors is uneven. At present, the most common use of post-anchoring in the curtain wall industry is chemical anchors. However, there are many chemical anchor brands, fish eye beads, and different quality. The anchoring glue of chemical anchors plays the role of bonding the concrete substrate to the anchor reinforcement.

At present, there are a variety of chemical binders on the market, the most common are modified epoxy resin, ethylene acrylic resin, and unsaturated resin three categories. The physical and chemical properties of anchor glue directly affect the anchoring effect, in addition to several imported well-known brand publicity materials marked with anchor adhesive durability, temperature resistance, freeze-thaw, and other test indicators, most manufacturers of product introduction only “acid and alkali resistance, anti-aging, heat resistance, low-temperature sensitivity” vague declaration. Although most of the on-site pull-out tests can meet the design requirements, because the durability of the anchor glue can only be predicted by laboratory tests, and the degree of influence of high welding temperature on the anchor glue, no one can say, the selection of chemical anchors must not be cheap, must choose each performance index in line with the design and specification requirements, and the market reputation of the good product.

To sum up, in order to ensure the safety of dry-hanging stone curtain walls, we must start with the most basic material selection, should not only consider the immediate benefits but use low-cost materials, which brings hidden dangers to safety. At the same time, it is necessary to strengthen the management of the construction process, do a good job in the disclosure and training of installation workers, enhance their awareness of quality and safety, and avoid potential safety hazards to the stone curtain wall due to irregular operation of workers or weak awareness of quality and safety. In short, we must make the stone curtain wall a beautiful landscape of urban architecture, rather than a time bomb