Stone electrolysis has appeared in the stone industry for more than ten years and has been widely recognized by producers and consumers. This is similar to the optimization of the jade jewelry industry. It is a kind of processing that combines nature and man, enriches the variety of stones, and improves the quality of the stone.

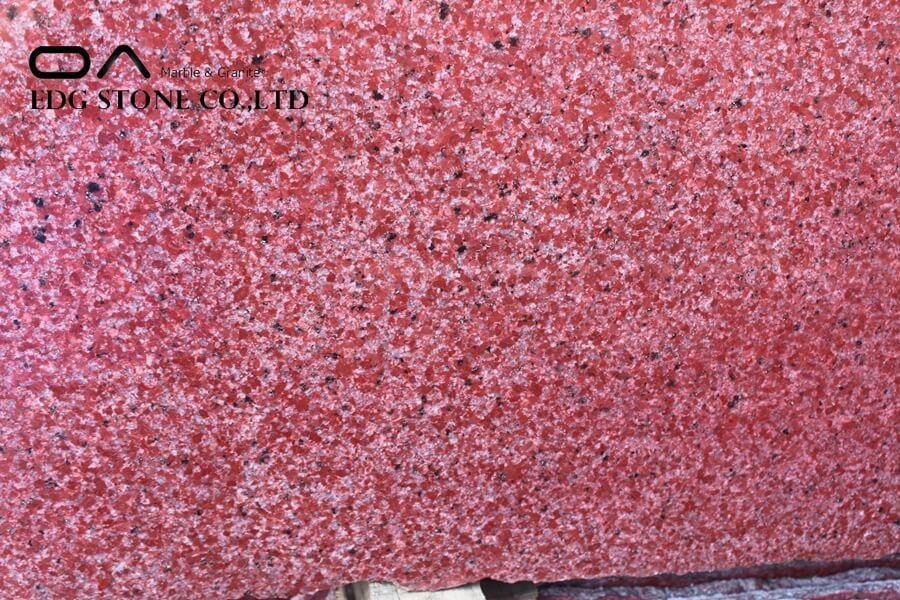

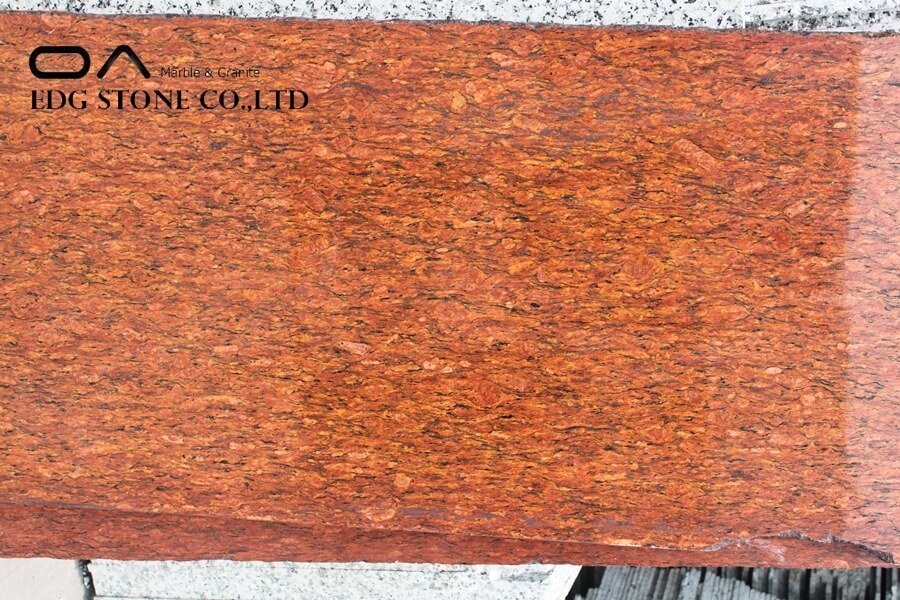

Electrolyzed stone is a natural stone artificially added to external factors, which causes the stone to undergo chemical and physical reactions at high temperatures, which causes the stone to change its color and become a new stone. This reaction is stable, that is to say, the timeliness of the electrolyzed stone Better, the color is very natural, very uniform, does not revert, and does not fade; the color of the fracture surface and the color of the surface are basically uniform.

In fact, in nature, this series of reactions is never interrupted, but due to the low temperature (compared with the electrolysis in the electrolytic furnace), the reaction is very slow and invisible.

The surface layer (or stone skin) of the stone in the mine is often different from the deep layer of stone. This is actually the “natural electrolysis” of the surface stone that is affected by the sun faster than the deep layer. The electrolysis of the stone is only an artificial increase in temperature, thus Speeding up this series of reactions, so electrolytic stone and natural stone are essentially the same.

“Electrolytic dyeing” and “dyeing” are essentially different

“Electrolytic dyeing” is no dyes added to the stone, but certain chemical raw materials, which participate in a series of reactions in the electrolysis process. Thus it becomes part of the stone.

The biggest difference between “electrolytic dyeing” and “traditional dyeing” is whether the raw materials or dyes have a chemical reaction and whether there is a high-temperature fixing process. Moreover, the raw materials added in the electrolysis are inorganic substances, and the dyes are organic substances.

Will the electrolytic stone fade?

Inorganic substances: such as glass, cement, stone, water, air, salt, metal, porcelain, clay, etc. These substances are stable at room temperature. Not easy to change color and fade. (Some metals oxidize and rust due to contact with water and air)

Organic matter: such as wood, plastic, clothing (cloth), oil (peanut oil, gasoline, diesel, paint, etc.), rubber, resin, fruit, grain, meat, etc. These substances will undergo deterioration and aging at room temperature, resulting in discoloration and fading.

Some people worry that electrolytically dyed stone is used as an exterior wall, and they are afraid that the color will fade due to the sun, but is the temperature of the sun being higher than the temperature of the electrolytic furnace? Electrolytic dyed stone is originally refined at high temperatures. Are you afraid of the sun?

Stone “Rust Lifting”

It can be said that “rust removal” refers to a color-yellow, and it is the primary or simplified version of “electrolytic dyeing” without high-temperature fixation. But there are also chemical reactions (reactions under natural room temperature), but the operation method is the same as traditional dyeing, mainly surface processing. (Electrolytic dyeing is more than one color)

Will the stone rust-lifting board fade?

1. Rust lifting is a simple version of electrolysis, which is the same as electrolysis and does not fade.

2. The yellow color in the rust-lifting board is actually “rust”, an inorganic salt, non-toxic, and the same composition as the rust in the rusted stone. Not afraid of the sun and rain.

3. The rust catalyst before the reaction is generally a solution, the size of the composition is ionic level, (average dozens of times smaller than nanometer), [Metalworking rust catalyst is a super concentrated crystal, it is also a solution after mixing with water], the solution is like water It can enter the interior of the stone (the stone has a certain water absorption rate). The rust catalyst enters the interior of the stone and reacts to form water-insoluble inorganic salt “rust”, and crystallizes (that is, becomes larger), and adsorbs each other with the stone. Can’t get out.

Stone electrolysis furnace

1. Main technical parameters

1. Rated voltage: three-phase 380V. Frequency: 50HZ.

2. Rated temperature: 450℃.

3. Heating element: SUS304# high-temperature stainless steel electric heating tube.

4. Furnace temperature uniformity: ±5℃.

5. Temperature control accuracy: ±2℃. (High-precision thyristor controlled heating)

6. Empty furnace power loss: ≤25KW.

7. Trolley movement: Fully automatic electric system control.

8. Furnace door lifting: automatic control of lifting and landing.

2. Comparison table of rated power, electrolytic stone output, and actual size:

Note: The maximum loading capacity is the maximum output of a one-time electrolysis stone. The total electrolysis process time is about 16 to 18 hours. The square meter loaded with stone is calculated as 2.5 meters long by 0.8 meters wide.

Three, product characteristics

1. Two microcomputer intelligent programming instruments are used to automatically control the temperature and heating. PID self-tuning control function can be programmed to set the heating curve in the furnace and the heating speed can be controlled. Furnace temperature uniformity: ±5℃.

2. The size and output of the electrolysis furnace can be customized according to requirements.

3. Yield rate: over 99%.

4. For granite stone: After the electrolysis of domestic white hemp, the white color is higher than that of American white hemp, which can completely change the domestic white hemp, significantly improve and become more advanced.

5. Light yellow stone: Shrimp red is electrolyzed into the pink stone slab.

6. Greenstone: Chengde green, China green, Jiangxi green, etc. are electrolyzed into brownstone slabs such as royal coffee, golden diamonds, and other stones. Mongolian butterfly green is similar to imported butterfly green after electrolysis.

7. The gray stone is electrolyzed into grayish-white or light green or golden yellow.

Stone continuous electrolysis furnace, stone continuous electrolysis production line

The stone electrolysis continuous furnace and the stone electrolysis continuous production line can achieve continuous electrolysis and uninterrupted operation, which is more energy-saving and faster. It can electrolyze more than 100 square meters of stone every 2 hours, which is especially suitable for the processing and production of large-scale stone enterprises. The number of combined monomer furnaces and electrolysis output can be configured according to customer requirements.