Carrying System for Porcelain Slab

Carrying System for Porcelain Slab Supplier In China

Carrying System for Porcelain Slab & Stone Slab Wedge - EDG

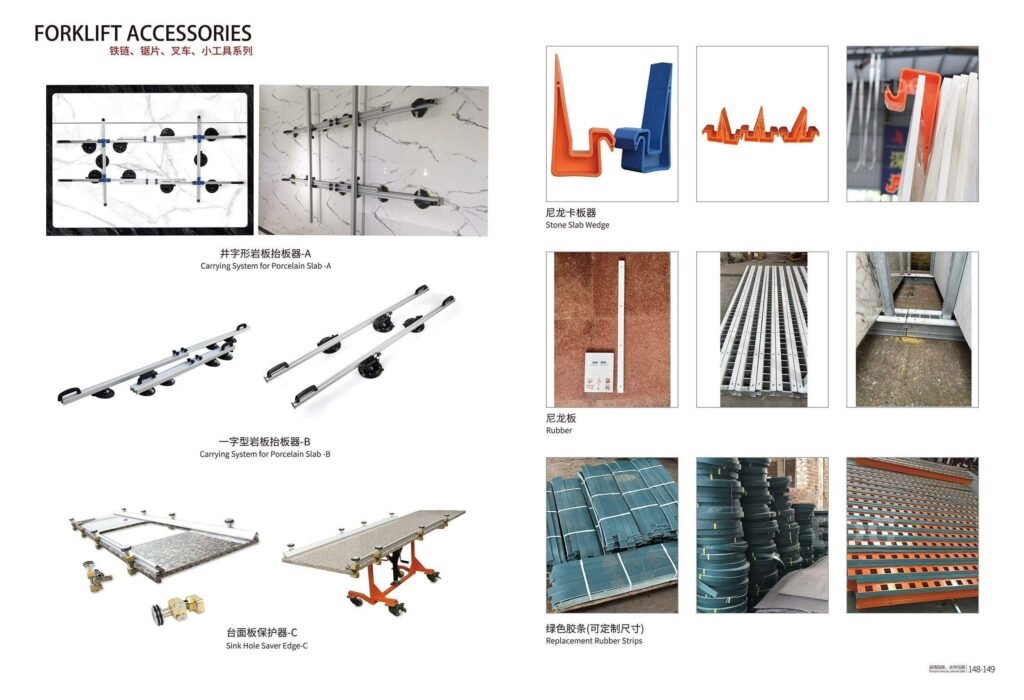

Our Carrying System for Porcelain Slab comprises a lightweight aluminum frame with adjustable clamp pads to grip large-format porcelain and sintered stone panels securely. The frame expands from 24″ to 144″ in width and accommodates thicknesses from 3 mm to 12 mm. Four heavy‑duty swivel casters—two with brakes—enable effortless maneuvering of slabs up to 2,200 lbs. Soft, replaceable rubber pads protect delicate edges from chipping, while quick‑release locking pins allow rapid frame resizing without tools. Fold‑flat handles provide ergonomic lifting points when manual carrying is required.

What makes this system stand out is its modular clamp design: individually spring‑loaded pads self‑adjust to surface irregularities and maintain constant clamping force. Compared to fixed‑size carts, our system adapts to multiple slab dimensions, reducing the need for different carriers. The entire assembly weighs under 45 lbs, yet meets ANSI A92 stability criteria for human‑powered transports. A corrosion‑resistant anodized finish and sealed bearings ensure long service life in wet or dusty environments. We provide custom pad materials—PP, PU, or silicone—for grip optimization and offer branded frame colors for large fleets. Backed by a 5‑year structural warranty and on‑site training, this carrying system boosts safety and throughput on tile and stone installation sites.

Our Stone Slab Wedge set provides a simple yet effective lifting and leveling solution for stone slabs during installation. Made from high‑strength, mold‑injected nylon, each wedge resists compressive forces up to 4,000 lbs without deformation. The serrated wedge profile locks firmly into rubber shim bases, preventing slippage under load. Wedges come in graduated heights from 1 mm to 10 mm, allowing installers to achieve precise leveling tolerances on countertops, thresholds, and coping stones. A high‑visibility orange color makes wedges easy to spot and remove after grout or adhesive cures.

Compared to traditional wooden shims, our Stone Slab Wedge offers reuse for hundreds of cycles and resists moisture, mold, and chemical attack from epoxies or silicone sealants. The abrasive‑safe nylon avoids marking or staining polished stone surfaces. Packs of 100 wedges, paired with 100 rubber shim bases, are supplied in a durable carry case with size‑labeled compartments. Bulk‑pack options come with custom insert trays for large projects. We back every set with a 2‑year performance guarantee, and replacement wedges and bases ship the same day. This wedge system minimizes installation time, reduces callbacks for uneven slabs, and delivers clear ROI for countertop fabricators and tile contractors.

RFQ About The Carrying System for Porcelain Slab & Stone Slab Wedge

Top 20 RFQ Q&A

Q: Width adjustment range?

A: 24″–144″.Q: Max load capacity?

A: 2,200 lbs.Q: Pad thickness range?

A: 3 mm–12 mm.Q: Frame weight?

A: 45 lbs.Q: Caster type?

A: 6″ swivel with brake.Q: Pad materials?

A: Rubber, PU, silicone.Q: Finish?

A: Anodized aluminum.Q: Assembly required?

A: Ships pre‑assembled.Q: Warranty?

A: 5 years on frame.Q: Bulk discounts?

A: Yes, for 10+ units.Q: Load rating per wedge?

A: 4,000 lbs.Q: Height increments?

A: 1 mm–10 mm.Q: Material?

A: High‑strength nylon.Q: Shim base?

A: Black rubber, non‑marking.Q: Kit size?

A: 100 wedges + 100 bases.Q: Reuse cycles?

A: 200+ cycles.Q: Case dimensions?

A: 12″ × 8″ × 2″.Q: Color?

A: High‑visibility orange.Q: Warranty?

A: Two years.Q: Bulk pricing?

A: Discounts of 10 kits.