What to consider when picking “the best” stone for a countertop

Table of Contents

Toggle- What to consider when picking “the best” stone for a countertop

- Head-to-head: common countertop stones (short summary + pros & cons)

- Durability & hardness — what the Mohs scale tells you

- Cost: what buyers actually pay (installed) — ballpark ranges and buying intent

- Industry trends & regulations shaping the countertop market

- Which stone should you pick? (scenario-based)

- Buying tips — manufacturer / factory / wholesale keywords & actions

- References & data sources (select key sources)

- SEO tags

- FAQ — top 5 Google-hot queries (visible Q&A)

“Best” is contextual. Before choosing, decide on (rank in order of priority):

Daily use & durability — Do you cook a lot, use hot pans, or need a surface that resists scratching and chipping?

Maintenance appetite — Will you reseal (natural stones) or prefer wipe-and-go (most quartz)?

Aesthetics — Do you want consistent veins/patterns (quartz) or one-of-a-kind natural slabs (granite, marble, quartzite)?

Budget & lifecycle cost — Upfront material + fabrication + installation vs. long-term maintenance costs.

Health & regulatory factors — Are you sourcing materials that require specific shop controls (silica exposure) or are under regulatory limits in your jurisdiction?

Resale and trends — Will your choice help resale or align with design trends? (Quartz’s popularity is high among designers.)

Head-to-head: common countertop stones (short summary + pros & cons)

Quartz (engineered)

What: Manufactured from crushed quartz + resins/pigments.

Pros: Very low maintenance (non-porous), stain-resistant, uniform look, broad color/pattern options, favored in modern kitchens.

Cons: Can be damaged by very high heat; heavy; some engineered products are subject to workplace silica regulations during cutting/fabrication. Quartz is currently the market leader in popularity among designers and homeowners.

Granite (natural)

What: Natural igneous stone with unique patterns and color variations.

Pros: High heat resistance, hard and durable (varies by type), classic natural stone look.

Cons: Slight porosity (needs periodic sealing), color/pattern variability (good and bad), exotic slabs can be pricey. Cost ranges vary widely by grade and origin.

Quartzite (natural)

What: A metamorphosed sandstone — often confused with engineered quartz but entirely natural.

Pros: Very hard (often ~7 Mohs), excellent scratch resistance, natural stone aesthetic similar to marble but tougher.

Cons: Can be porous and may need sealing; slab availability and price vary; fabrication requires skill.

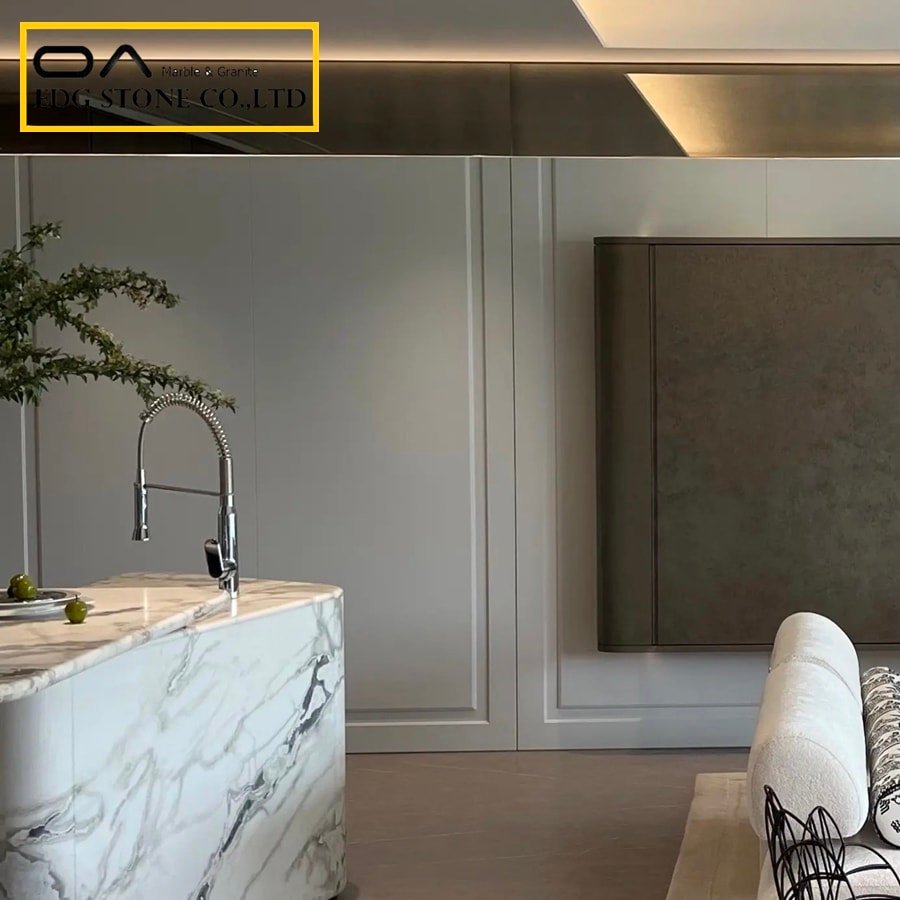

Marble

What: Metamorphic stone prized for its veining and luxury look.

Pros: Iconic beauty, cool to touch (great for baking tasks).

Cons: Softer (more prone to scratching & etching from acids), high maintenance—needs sealing and careful use.

Soapstone

What: Dense natural stone (mostly talc + silicate minerals).

Pros: Heat and stain-resistant; develops a patina; requires minimal sealing (often just mineral oil).

Cons: Softer (scratches can occur), but scratches can be buffed out.

Porcelain slabs (sintered stone)

What: Man-made, kiln-fired large-format slabs, not stone but highly engineered.

Pros: Extremely stain, scratch, and heat resistant; ultralight options are available; consistent.

Cons: Edge fabrication can be tricky; it requires specialized tools and installers.

Durability & hardness — what the Mohs scale tells you

Hardness matters for scratch resistance and everyday durability. Typical Mohs values (approx):

Quartz / Engineered quartz: ~7 (because quartz mineral) — excellent scratch resistance.

Quartzite: ~7 — often harder than most granites; very scratch-resistant.

Granite: ~6–7 (varies by composition) — very durable overall.

Marble: ~3–4 — softer, scratch- and acid-prone.

Soapstone: ~1–3 depending on composition (softer but workable).

Takeaway: If scratch resistance is #1, quartz and quartzite are top picks. For heat and impact, granite and quartzite perform well.

Cost: what buyers actually pay (installed) — ballpark ranges and buying intent

Countertop prices depend on slab grade, fabrication complexity, edge profile, sink cutouts, and regional labor. Typical installed ranges (industry averages as reported in 2024–2025 sources):

Quartz (engineered): roughly $50–$200 per sq ft installed, depending on brand/veining/collection.

Granite: roughly $50–$225 per sq ft installed (level/grade and exotic slabs push cost up).

Marble: often $125+ per sq ft installed, higher for premium stones.

Quartzite & Porcelain slabs: widely variable — premium quartzite and large-format porcelain can exceed $150–$250+/sq ft installed.

Which is cheaper — granite or quartz?

Entry-level granite can be cheaper than branded designer quartz, but mid-range quartz often undercuts exotic granite. Overall, either can be cheaper depending on grade and brand — check quotes from local fabricators and wholesale slab importers.

Industry trends & regulations shaping the countertop market

Two converging trends are changing how buyers and manufacturers source and produce countertops:

Quartz popularity & market growth. Quartz (engineered) continues to grow in market share thanks to low maintenance and wide design options; industry reports show strong quartz market valuations and growth projections. Quartz’s versatility keeps it the leading choice in modern kitchen designs.

Worker safety and engineered-stone regulation. A major regulatory development: Australia adopted a ban on the use, supply ,and manufacture of engineered stone that contains high crystalline silica, effective 1 July 2024, with import restrictions phased in (some jurisdictions moved to ban importation from Jan 1, 2025). The ban followed a public-health crisis of work-related silicosis among engineered-stone workers and reflects a global focus on silica exposure controls. Manufacturers, importers, and shops must now monitor regulations closely — similar occupational-safety scrutiny and tighter silica controls are being discussed in other jurisdictions too. If you buy engineered products, verify your fabricator’s exposure controls, certifications, and country-specific rules.

Why this matters to buyers & suppliers: Some engineered quartz lines or imported slabs may become harder to source or more costly as compliance costs rise; suppliers who advertise “engineered stone – manufacturer/factory compliant with silica controls” will have a market advantage.

Which stone should you pick? (scenario-based)

Busy family kitchen, minimal upkeep: Quartz — non-porous, low maintenance, stain-resistant.

Frequent high-heat use (hot pans) & classic natural look: Granite or quartzite — excellent heat resistance (but still use trivets).

Want marble look but can’t accept etching: Engineered quartz with marble veining or porcelain slab — gives look without marble’s maintenance.

Looking for the toughest natural stone: Quartzite or high-grade granite — top on the Mohs scale and impact resistance.

Budget-first, short-term flip project: Laminate or entry-level granite — lower upfront cost and quick install.

Buying tips — manufacturer / factory / wholesale keywords & actions

When you’re in procurement mode (especially B2B or large projects), use long-tail purchase-intent keywords and actions:

Suggested long-tail buyer keywords (3–5 as requested):

“wholesale quartz slab manufacturer factory price”

“granite slab supplier manufacturer bulk wholesale”

“Buy quartzite countertops from a factory export manufacturer.”

“engineered quartz manufacturer compliant silica controls”

“porcelain slab wholesale supplier large format factory”

Practical actions:

Ask suppliers for SDS (safety data sheets) and fabrication safety certifications if they supply engineered stone.

Request sample slabs and detailed installation quotes, including edge work, seams, and templating fees.

Confirm lead times and MOQ for slab imports — some suppliers advertise “no MOQ” but check shipping and customs.

Check warranty terms (some quartz brands offer strong product warranties that add resale value).

References & data sources (select key sources)

(These support the cost, trend, and regulation claims made above.)

Quartz vs Granite cost comparison — HomeGuide (Jan 2024).

Countertops market & trend analysis — Grand View Research (countertops market report).

Australia engineered stone ban — Safe Work Australia (WHS minister’s decision; ban effective July 1, 2024).

Industry legal/regulatory analysis — Norton Rose Fulbright on silica regulation & jurisdiction summaries.

Cost / installed ranges & consumer guides — GWSurfaces / BadgerGranite / Home Depot service pages.

Mohs hardness and stone hardness references — All American Granite / Tenax resources.

SEO tags

best stone for a countertop, kitchen countertop stone, quartz vs granite, quartz countertop cost, granite countertop price, quartzite countertop, marble countertop care, toughest stone countertop, durable stone countertops, cheapest countertop stone, porcelain countertop slab, engineered quartz manufacturer, wholesale quartz slabs, granite wholesale factory, buy quartz slabs, countertop manufacturers, countertop suppliers, wholesale countertops, stone countertop factory, quartz slab supplier, quartz countertop installation, granite countertop installation, countertop maintenance guide, stone countertop durability, stone countertop trends 2025, silica regulations engineered stone, engineered stone ban Australia, countertop market share quartz, kitchen countertop trends, countertop material comparison, Mohs hardness countertops, stain resistant countertops, heat resistant countertops, best countertop for families, low maintenance countertops, luxury stone countertops, cost per square foot quartz, cost per square foot granite, quartzite vs quartz, where to buy quartz countertop, lab-tested quartz safety, eco-friendly countertop materials, recycled quartz countertops, porcelain slab countertops, marble alternative quartz, stone countertop warranty, buying countertops wholesale, factory direct countertops, countertop slabs import.

FAQ — top 5 Google-hot queries (visible Q&A)

What type of stone is best for kitchen countertops?

Answer: It depends on your priorities. For low maintenance and consistent appearance, engineered quartz is usually best. For natural hardness and heat resistance, quartzite or premium granite is excellent. Consider cost, maintenance, and local safety/regulation issues when choosing.Which stone countertop is most durable?

Answer: Quartzite and high-grade granite typically rate highest for scratch and heat resistance (Mohs ~7 for quartzite; granite typically 6–7), while engineered quartz offers consistent hardness and excellent resistance to staining.Is granite or quartz better for counters?

Answer: Both have strengths. Quartz is non-porous and low-maintenance; granite is very heat-resistant and naturally unique. Choose quartz for maintenance ease; choose granite for natural stone aesthetics and higher heat tolerance.What is the most popular countertop right now?

Answer: Engineered quartz ranks as the most popular material in current kitchen trends for its maintenance profile and design flexibility. Designer reports and market studies show quartz leading new countertop installations.What is cheaper, granite or quartz?

Answer: Prices overlap. Entry-level granite can be cheaper than premium quartz lines, but mid-range quartz is often price-competitive. Always compare installed quotes, including fabrication and edge detail, for an apples-to-apples comparison.

Semantic closure & interpretation block — How / Why / What / Options / Considerations

Why: Quartz leads in popularity because it bundles consistent aesthetics and minimal maintenance; natural stones (granite/quartzite) retain value for their unique patterns and high heat/scratch resistance.

What: Options include engineered quartz (low maintenance), granite (natural resilience), quartzite (top natural hardness), porcelain (cutting-edge tech), and marble (luxury but high care).

Options (detailed): For heat + scratch priority → quartzite or granite. For maintenance + resale → quartz. For budget or quick flips → laminate or entry-level granite. For eco-focus → recycled quartz or low-embodied-carbon porcelain/ceramics where available.

Considerations (detailed): 1) Always request SDS and fabrication safety protocols for engineered stone; 2) confirm sealing schedule for natural stones; 3) get installed quotes (not just material). Regulatory shifts (e.g., engineered-stone bans in some countries) can affect supply and compliance costs — verify before placing large orders.