What is the highest quality countertop?

Table of Contents

Toggle- What is the highest quality countertop?

- How we define “highest quality”?

- Top countertop materials (ranked by quality attributes)

- 1) Sintered / compact surfaces — top for technical durability

- 2) High-grade Engineered Quartz — best balance of aesthetics + low maintenance

- 3) Granite & Quartzite — natural stone heavyweights

- 4) Large-format Porcelain slabs — high-performance, design-flexible

- 5) Marble — unmatched luxury appearance, but softer

- 6) Solid Surface (Corian and equivalents) — seamless design and repairability

- Comparative snapshot (high-level)

- Regulations & industry trends that change how “quality” is measured

- Real-world selection scenarios (how to pick by use case)

- Buying checklist & factory/manufacturer considerations

- FAQ — Google hot questions (5 answers)

- Semantic closing block — How / Why / What / Options / Considerations

- 50 SEO tags

How we define “highest quality”?

“Highest quality” is multidimensional. To avoid the marketing trap of a single answer, consider these axes:

Durability & hardness: resistance to scratches, abrasion, and chips.

Heat resistance: how well the surface tolerates hot cookware.

Stain resistance & porosity: whether liquids penetrate and how sealing is required.

Appearance & consistency: natural uniqueness vs. manufactured uniformity.

Repairability & longevity: ease of restoration after damage.

Safety & compliance: fabrication risks (e.g., silica exposure) and regulatory status.

Sustainability & lifecycle cost: environmental impact, embodied energy, and long-term ownership costs.

Different use cases weight these axes differently (e.g., a professional kitchen prioritizes heat and scratch resistance, a luxury bathroom prioritizes appearance).

Top countertop materials (ranked by quality attributes)

1) Sintered / compact surfaces — top for technical durability

Why they rank high: products like Dekton and Neolith are manufactured via extreme heat and pressure into highly dense slabs. They offer exceptional scratch resistance, low porosity (near-zero), and excellent thermal shock resistance, making them ideal for heavy-use kitchens, exterior applications, and integrated surfaces. They are also UV-stable for outdoor use and come in very large formats for minimal seams.

Tradeoffs: cutting and fabricating sintered surfaces require specialized tooling; installers may charge premiums. Color/edge options are improving, but can be less forgiving than natural stone for very specific veining effects.

2) High-grade Engineered Quartz — best balance of aesthetics + low maintenance

Why they rank high: engineered quartz (composed of ~90–94% natural quartz + resins and pigments) combines extreme hardness, stain resistance, and a wide palette of consistent designs (including convincing marble patterns). High-end brands and thicker slabs give premium durability with very low maintenance and no sealing required. Many homeowners favor quartz for its lifetime value.

Tradeoffs: quartz can discolor with high heat (resins can char), and the biggest concern for fabricators is respirable crystalline silica when cutting engineered stone—this has triggered tighter regulation and, in some places, bans on engineered stone production or importation.

3) Granite & Quartzite — natural stone heavyweights

Why they rank high: many granites and quartzites are extremely hard and heat-resistant. Quartzite, a metamorphic natural stone, often outperforms granite for heat and scratch resistance while offering dramatic natural veining. Natural stone’s uniqueness and longevity make it a top choice for owners who prize authenticity.

Tradeoffs: natural variability (beauty is variable) and porosity (some varieties require sealing). Sourcing and ethical quarrying vary by supplier.

4) Large-format Porcelain slabs — high-performance, design-flexible

Why they rank high: porcelain slabs are non-porous, chemically inert, and highly resistant to stains, heat, and UV. They’re available in ultra-large formats for near-seamless installations and imitate stone and metallic looks well. They are lightweight compared to stone of similar thickness, easing installation in some contexts.

Tradeoffs: porcelain can chip, and sharp impacts can fracture thin slabs; specialized tools are required for fabrication.

5) Marble — unmatched luxury appearance, but softer

Why they rank high (aesthetic quality): no other material matches natural marble’s depth, translucency, and luxury appeal. For design-led, low-traffic counters (bathroom vanities, feature islands), marble is top-tier.

Tradeoffs: marble is softer and more porous than quartz or sintered surfaces; it stains and scratches more easily and typically requires regular sealing and careful use.

6) Solid Surface (Corian and equivalents) — seamless design and repairability

Why it ranks high: solid surface materials offer seamless joins, integrated sinks, and are readily repairable (scratches can be sanded out). They excel in commercial environments where hygiene and seamless joints matter (healthcare, labs, bathrooms).

Tradeoffs: softer than quartz and sintered surfaces; more prone to heat damage and visible scratches in heavy-use kitchens.

Comparative snapshot (high-level)

Hardness (best → worst): Sintered ≈ High-grade quartz > Quartzite ≈ Hard granite > Porcelain > Marble > Solid surface.

Porosity (least → most): Sintered ≈ Porcelain ≈ , High-grade quartz < Granite/Quartzite < Marble < Solid surface.

Heat resistance (best → worst): Sintered > Quartzite > Granite > Porcelain > Quartz > Marble > Solid surface.

Maintenance (low → high): Sintered/Porcelain/Quartz (low) < Granite/Quartzite (moderate, sealing) < Marble/Solid surface (higher).

(These generalizations align with product specs and industry testing; consult manufacturer datasheets for exact ratings.)

Regulations & industry trends that change how “quality” is measured

Recent regulatory and enforcement actions are reshaping which countertops are practical and how fabricators price and deliver “quality”:

Respirable crystalline silica enforcement (OSHA and equivalents): regulators emphasize wet cutting, local exhaust ventilation, and exposure monitoring for stone fabrication to prevent silicosis and lung disease. OSHA guidance and inspection initiatives aim to reduce worker exposure—this increases fabrication costs and may influence buyer pricing and availability.

Engineered stone bans and import controls (Australia as an example): some jurisdictions (notably Australia) have implemented bans or strict controls on engineered stone (high-silica quartz) due to documented silicosis clusters among fabricators; import and manufacture bans came into effect nationally in 2024–2025 in Australia, affecting global supply chains and market perception. Buyers in affected regions must pivot to alternatives or ensure compliant sourcing. safeworkaustralia.gov.au+1

Buyer preference shifts: design trends and consumer preferences increasingly favor low-maintenance surfaces (quartz, sintered) and large-format, seam-minimizing installations; at the same time, a renewed interest in “honest” natural stone finishes (honed, leathered) is pushing granite back into play for some audiences.

Implication: “Highest quality” is no longer just a product property — it includes the fabricator’s safety practices, traceability of material, and compliance. Buyers should ask fabricators how they control silica, what protective systems are used, and whether imported materials comply with local regulations.

Real-world selection scenarios (how to pick by use case)

Busy family kitchen (daily heavy use): prioritize low maintenance and durability — sintered surfaces or high-grade quartz.

Professional or restaurant kitchen (hot pans & heavy use): choose sintered surfaces or hard quartzite/granite for heat and abrasion resistance.

Luxury center-island feature (show-stopping looks): consider marble for drama (with protective strategies), bookmatched quartzite, or engineered quartz with premium veining for consistency plus low maintenance.

Bathroom vanity or integrated sink applications: solid surface (Corian) excels for seamless troughs and repairability.

Outdoor kitchens: favor sintered surfaces or porcelain for UV stability and freeze/thaw performance.

Buying checklist & factory/manufacturer considerations

Ask the manufacturer/factory for technical data sheets (hardness, thermal tolerance, porosity).

Verify compliance & safety practices: for engineered stone, ask how slabs are produced and how fabricators handle silica exposure. For imported materials, confirm whether import restrictions apply in your country. safeworkaustralia.gov.au+1

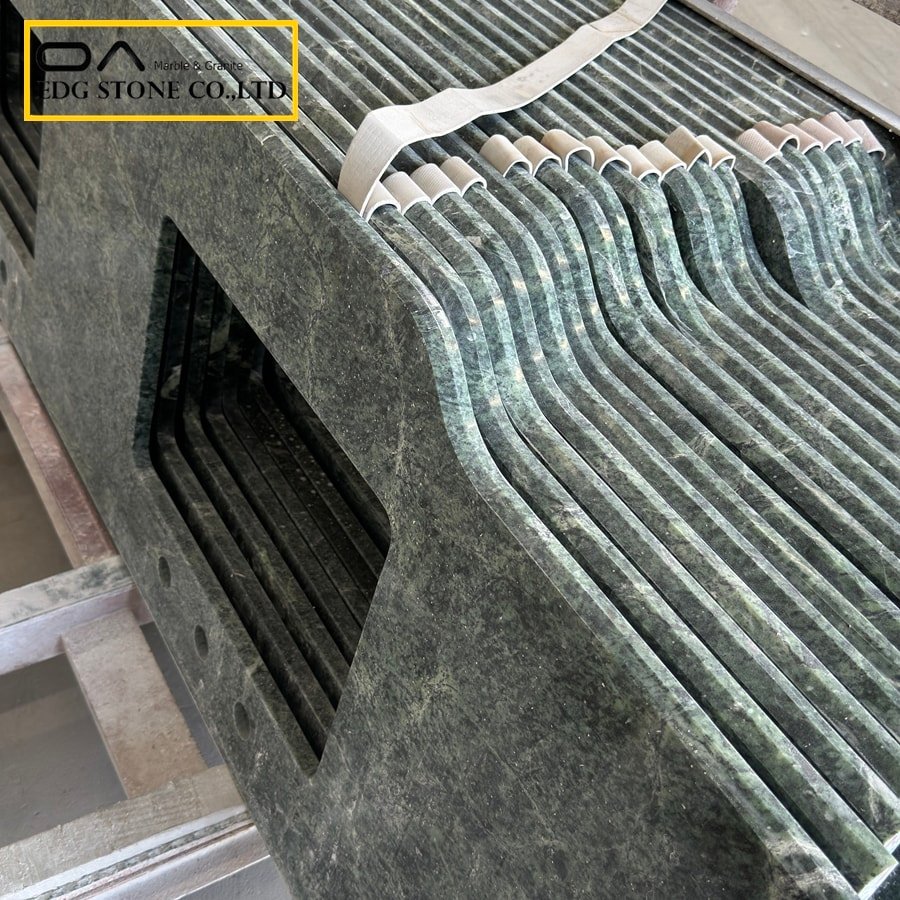

Request real slab or sample photos, and if possible, see full slabs on site.

Confirm warranty & repair policies (heat damage exclusions, seam adhesives, maintenance).

Assess installation complexity — large-format or heavy slabs may require reinforcement, specialized transport, and premium installers.

FAQ — Google hot questions (5 answers)

What is the highest quality countertop material?

Answer: The “highest quality” depends on priorities. For technical durability and low maintenance, sintered/compact surfaces (e.g., Dekton, Neolith) and premium engineered quartz are top-ranked; for natural beauty and elemental uniqueness, quartzite and selected granites are highest quality. Regulatory and fabrication-safety practices now factor into the definition of quality as well.What is the most luxurious countertop?

Answer: Natural marble (rare types, bookmatched), exotic onyx, and highly figured quartzite are typically considered most luxurious for appearance, though luxury can also mean bespoke engineered designs or bookmatched slabs that create a dramatic centerpiece.Which is better, quartz or granite?

Answer: Quartz (engineered) is typically better for low maintenance and consistent appearance—non-porous and never needs sealing—while granite offers natural variation and heat resistance; high-end granite can be nearly as durable but often requires periodic sealing. Choose quartz for maintenance ease and granite for natural aesthetics.Why don’t people use granite anymore?

Answer: Granite declined in popularity in the 2010s as engineered quartz rose—quartz offers cleaner, uniform looks, easier maintenance, and predictable pricing. However, granite remains widely used and has been seeing renewed interest with new finishes (honed, leathered) and colors; it hasn’t disappeared, it simply ceded mindshare to low-maintenance alternatives.Is Corian or quartz better?

Answer: It depends on needs. Corian (solid surface) is superb for seamless integration, easy repairs, and custom sinks—excellent in bathrooms and commercial spaces. Quartz is harder, more scratch- and heat-resistant, and better for heavy-use kitchen counters. For a kitchen island, quartz typically outperforms Corian; for integrated sinks and seamless wet-area design, Corian is advantageous.

Semantic closing block — How / Why / What / Options / Considerations

Why: Why these materials top the list — manufacturing (sintering, engineered quartz) controls porosity and hardness; natural stone offers geologic rarity and aesthetic value. Recent regulation and safety enforcement mean that the fabricator’s practices (silica control, wet cutting, HEPA extraction) are now part of product quality and true lifecycle cost.

What: What to verify with your supplier/factory — technical datasheets, compliance (silica controls), warranty terms, actual slab photos, and installation logistics. Demand transparent answers about workplace safety and fabrication methods.

Options: Consider hybrid approaches—**use sintered or quartz for primary prep areas** and **marble or bookmatched stone as feature surfaces** to balance durability with luxury. For outdoor kitchens, prefer UV-stable sintered or porcelain.

Consideration: Factor in the total cost of ownership (initial price + maintenance + potential replacement + health/safety compliance). A “cheap” countertop today can become expensive if it requires frequent sealing, specialized repairs, or if its fabrication involved non-compliant practices that later trigger liabilities or supply interruptions.

50 SEO tags

50 SEO tags (mix of intent, product, and long-tail):

highest quality countertop, best countertop material 2025, most luxurious countertop, quartz vs granite which is better, top of the line countertop, is granite out of style, Corian vs quartz comparison, sintered countertop vs quartz, Dekton countertop quality, Neolith vs quartz, quartzite countertops pros cons, best kitchen countertop for durability, porcelain slab countertops, marble luxury countertops, engineered stone regulations, silica exposure countertop fabrication, quartz manufacturer wholesale, countertop factory supplier, buy high-end countertops, best countertop for resale, countertop maintenance costs, countertop longevity comparison, heat resistant countertops, scratch resistant countertops, best countertop for busy kitchen, countertop installation checklist, countertop warranty and care, top countertop materials list, countertop sustainability, high-end quartz brands, stone slab manufacturer, large format porcelain slab supplier, countertop edge profile guide, countertop buying tips, quartz slab wholesale price, granite vs quartzite pros cons, engineered quartz safety, best countertops for outdoor kitchen, seamless countertops Corian, integrated sink materials, luxury countertop trends 2025, countertop compliance silica OSHA, kitchen design countertop choices, countertop cost per square foot, countertop repairability, porcelain vs sintered differences, countertop finish types, premium countertop suppliers, natural stone bookmatch, countertop performance ratings.