Pros and Cons of Natural vs. Engineered Stone

Table of Contents

Toggle- Pros and Cons of Natural vs. Engineered Stone

- What Is Engineered Stone?

- Composite Stone: Is It Right For You?

- Engineered Stone Countertops: A Buyer’s Guide – EDG Stone

- Engineered Quartz Countertops: All You Need to Know

- Beginner’s Guide to Engineered Quartz Countertops

- Types Of Engineered Stone Countertops

- FAQ

- Conclusion

- References

Before exploring engineered stone composite, it’s essential to compare it with its natural counterpart.

Pros of Natural Stone

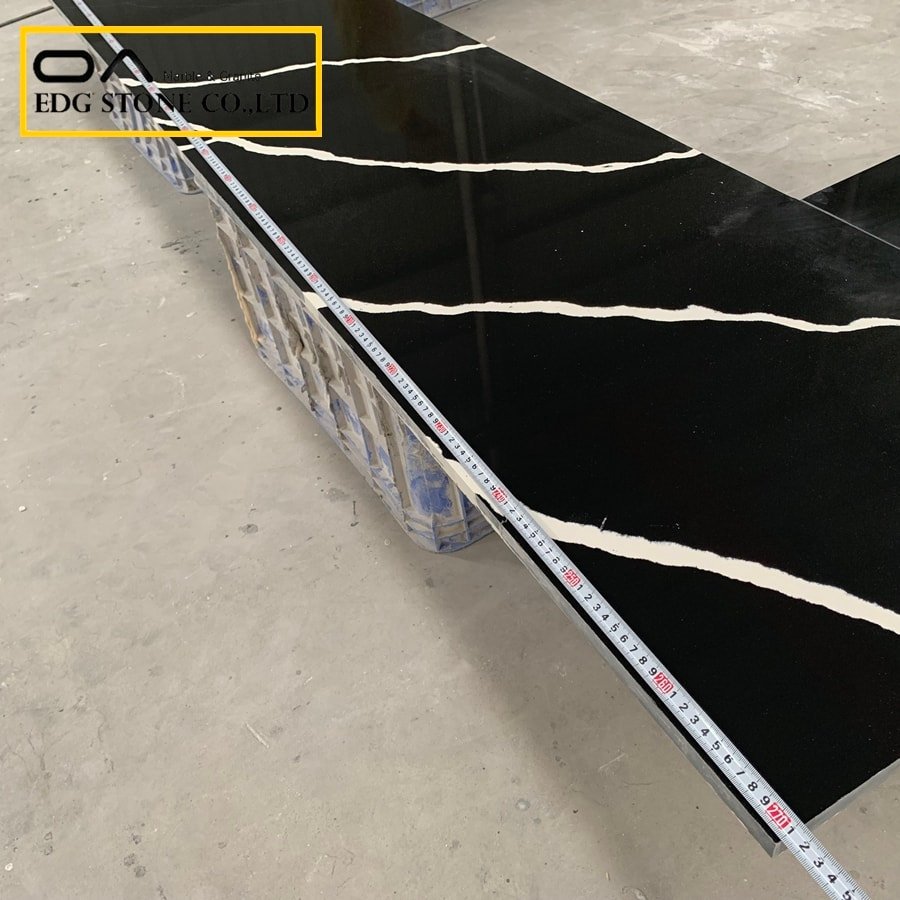

Unique Veining & Color Variations: Each slab is one-of-a-kind.

Heat Resistance: Can handle higher temperatures without damage.

Perceived Luxury: Often considered a premium, high-end material.

Cons of Natural Stone

Porosity & Sealing: Requires periodic sealing to prevent stains.

Inconsistent Patterns: May present unsightly blemishes or fissures.

Higher Cost: Exotic marbles and granites can exceed $200 per sq. ft. installed.

Pros of Engineered Stone

Uniform Appearance: Consistent color and pattern across slabs.

Non-Porous & Low Maintenance: No sealing required, highly stain-resistant.

Durability: Resistant to scratches, impact, and moderate heat.

Design Versatility: Pigments and additives enable dozens of colors and finishes.

Cons of Engineered Stone

Heat Sensitivity: Prolonged exposure to extreme heat can discolor or damage the resin.

Cost: Mid-range engineered quartz typically runs $50–$120 per sq. ft. materials only.

Environmental Impact: Manufacturing involves resins and polymer binders, raising sustainability concerns.

What Is Engineered Stone?

Engineered stone is a man-made composite consisting primarily of:

Crushed Natural Stone Aggregates (often 90–95% quartz, granite, marble, or recycled glass)

Polymer Resin Binders (usually polyester or epoxy resins)

Color Pigments & Additives (for UV protection, enhanced hardness, or antimicrobial properties).

Manufacturing Process (H3)

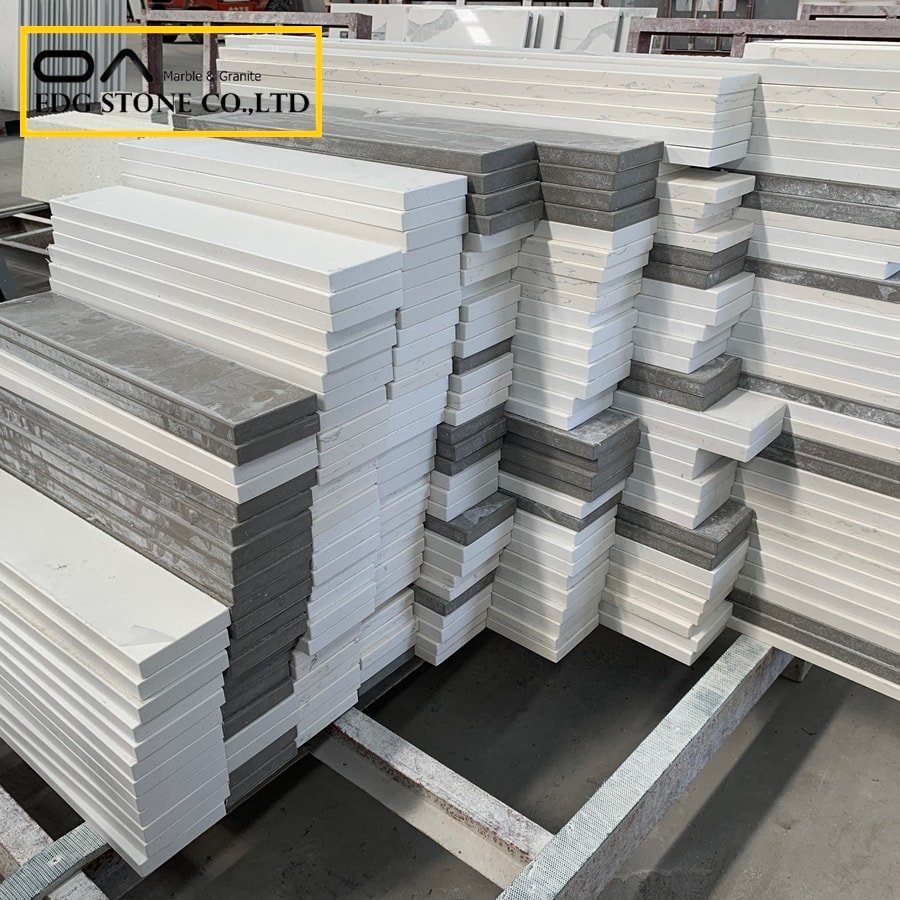

Aggregate Preparation: Natural stone is crushed and screened by size.

Mixing: Stone aggregate blends with resins, pigments, and catalysts.

Molding & Compression: The mixture is cast into slabs under high pressure and vibration to minimize voids.

Curing & Polishing: Slabs cure in ovens, then are ground and polished to a glossy finish.

Because of this controlled process, engineered stone delivers consistent thickness, uniform patterns, and minimal fissures, making fabrication and installation more predictable than natural stone.

Composite Stone: Is It Right For You?

“Composite stone” is often used interchangeably with “engineered stone,” but can also refer more broadly to any stone-resin blend (including cultured marble or terrazzo). To decide if engineered stone composite suits your needs, evaluate:

Budget & Value: Starting at $50 per sq. ft. material (installed $75–$200).

Design Goals: Want exact color matching across multiple slabs? Engineered stone excels.

Maintenance Tolerance: For homeowners who dislike sealing natural stone, the worry-free care of engineered surfaces is a major plus.

Environmental Priorities: Seek recycled content or low-VOC resins; look for certifications like Greenguard or NSF.

Engineered Stone Countertops: A Buyer’s Guide – EDG Stone

Top Engineered Stone Brands

Cambria: 100% quartz, 30+ colors, $70–$120 per sq. ft. installed.

Caesarstone: Pioneering brand with antibacterial protection, $65–$110 per sq. ft. installed.

Silestone by Cosentino: Incorporates HybriQ+ sustainable resin, $60–$125 per sq. ft. installed.

Key Buying Tips

Request Full Slab View: Unlike natural stone, even engineered patterns can vary by batch.

Check Edge Profiles: Eased edge is standard; waterfall or ogee edges add $15–$30 per linear foot.

Ask About Seaming: Well-fitted seams are nearly invisible; ensure your fabricator uses color-matched epoxy.

Compare Warranties: Many brands offer 10–25 year limited warranties covering manufacturing defects.

Engineered Quartz Countertops: All You Need to Know

Since quartz is the most common aggregate in engineered stone, “engineered quartz” has become synonymous with “engineered stone.”

Composition: 90–95% ground quartz crystals + 5–10% polymer resin and pigments.

Performance: Non-porous, scratch-resistant, UV-stable (some brands caution against direct outdoor use).

Applications: Kitchen countertops, bathroom vanities, backsplashes, flooring, and even wall cladding.

Beginner’s Guide to Engineered Quartz Countertops

Installation Steps

Measurement & Template: Accurate CAD or cardboard templates for sink and cooktop cut-outs.

Slab Selection & Inspection: Verify batch consistency and absence of manufacturing defects.

Fabrication: CNC routing for edges, seams, and cut-outs.

Dry Fit & Seaming: Test seams, apply color-matched epoxy.

Setting & Leveling: Use mastic or thinset; shim cabinets for perfect level.

Joint Filling & Polishing: Final buffing to blend seams and edges flawlessly.

Maintenance Tips

Daily Cleaning: Mild dish soap and water; avoid bleach or harsh chemicals.

Stain Removal: For stubborn spots, use a non-abrasive cleaner; avoid steel wool.

Heat Protection: Always use trivets or hot pads to prevent resin discoloration.

Scratch Prevention: Although scratch-resistant, don’t cut directly on the surface.

Types Of Engineered Stone Countertops

Quartz-Based Engineered Stone (e.g., Cambria, Caesarstone)

Porcelain Slabs (e.g., Dekton, Neolith)—sintered at extreme heat, ultra-thin profiles.

Recycled Glass Composites (e.g., Vetrazzo)—offering translucent sparkle.

Cultured Marble & Cultured Stone—polyester resin with marble dust, common in bathrooms.

Terrazzo Engineered Stone—traditional cement or resin base with marble aggregate.

FAQ

Q1: Is engineered stone as good as quartz?

Yes—engineered quartz is engineered stone. All engineered quartz slabs are a type of engineered stone composite Reddit.

Q2: What are the disadvantages of engineered stone?

Heat sensitivity, potential UV-induced discoloration, and reliance on synthetic resins—factors in cost and sustainability.

Q3: Is engineered stone better than granite?

Engineered stone offers uniformity and non-porosity; granite is more heat-resistant and unique but requires sealing.

Q4: How long does engineered stone last?

With proper care, engineered stone countertops last 15–30 years—often backed by 10–25 year manufacturer warranties.

Q5: How expensive is engineered stone?

Typically $50–$120 per sq. ft. material, $75–$200 per sq. ft. installed, depending on brand and edge detail.

Q6: Which is better, porcelain or engineered stone?

Porcelain slabs are ultra-heat-resistant and UV-stable for outdoors; engineered stone offers warmer textures and greater impact resistance.

Q7: Does engineered stone scratch easily?

No—engineered stone is highly scratch-resistant, but avoid direct cutting or dragging heavy cast-iron across it.

Q8: How can you tell if a stone is engineered?

Look for repeating patterns across slabs, perfectly straight edges, and a lack of natural fissures.

Q9: Does engineered stone stain easily?

No—its non-porous surface resists common household stains; wipe spills promptly to maintain shine.

Q10: How do you maintain engineered stone?

Daily cleaning with mild soap and water; avoid harsh chemicals and protect from extreme heat.

Q11: Is engineered stone waterproof?

Effectively, yes—the resin-bonded surface prevents water penetration, making it ideal for kitchens and bathrooms.

Q12: How do you clean engineered stone stains?

Use a non-abrasive cleaner (e.g., pH-neutral spray), soft cloth, and gentle circular motions.

Q13: What are the disadvantages of engineered stone countertops?

Heat sensitivity, higher upfront cost than laminates, and the environmental impact of resins.

Q14: Which is better, quartz or engineered stone?

They’re the same: “quartz” is the aggregate; “engineered stone” is the category.

Conclusion

Engineered stone composite merges the best of natural stone aesthetics with modern manufacturing control, yielding a surface that’s durable, consistent, and low-maintenance. Whether you prioritize color uniformity, ease of care, or a wide palette of designs, engineered stone—particularly engineered quartz—stands out as a premier choice for countertops, vanities, and more. As you plan your project, weigh factors like cost ($50–$120 per sq. ft. material), brand warranties, and environmental credentials to select the perfect slab.

SEO Tags (30):

engineered stone composite, composite stone vs engineered stone, what is composite stone, engineered stone中文, what is engineered stone vs quartz, engineered stone vs quartz price, is engineered stone quartz, is quartzite engineered stone, engineered stone countertops, engineered quartz countertops, quartz engineered stone, quartz vs granite price, porcelain vs engineered stone, composite stone sink, engineered stone manufacturer, engineered stone supplier, engineered stone factory, buy engineered stone, engineered stone wholesale, engineered stone cheap, high quality engineered stone, China engineered stone, eco-friendly engineered stone, engineered stone durability, engineered stone FAQ, engineered stone maintenance, engineered stone color options, engineered stone brands, engineered stone pros and cons, engineered stone installation cost

References

Top’s Countertops. “Natural Stone vs. Engineered Stone Countertops.” 2023.

EDG Stone. “Composite Stone vs. Engineered Stone.” EDGStone.com, 2025. Edgstone

ED Stone Inc. “Understanding the Cost Differences: Natural Stone vs. Engineered Stone.” EDStoneInc.com, Aug 4, 2024.