How is quartz stone made?

Table of Contents

Toggle- How is quartz stone made?

- Natural quartz, quartzite, and engineered quartz — the difference

- How is quartz made in nature?

- How is engineered quartz made? A step-by-step walk-through

- How are granite countertops made? (Short comparison)

- Regulations, worker safety, and why this matters now

- Market context & data (what the numbers say)

- Common problems with quartz countertops — causes & fixes

- How to make quartz countertops shine (practical steps)

- Problems with quartz countertops that buyers should ask about

- How to make quartz slabs in Minecraft (fun short guide)

- Buying considerations — manufacturer, factory & wholesale tips

- Semantic closure: How/Why/What/Options/Considerations

- FAQ — 5 Google hot search style questions (original text + structured JSON-LD)

- Long-tail keywords, 50 SEO tags

Natural quartz, quartzite, and engineered quartz — the difference

People often use “quartz” loosely. Technically:

Natural quartz (mineral): silica (SiO₂) crystal; a component of many rocks.

Quartzite: a natural metamorphic rock formed when sandstone with high quartz content is subjected to heat and pressure; often used as a natural stone countertop.

Engineered quartz (commonly sold as “quartz countertops”): a manufactured surface made by combining crushed quartz (usually 90–95% by weight), pigments, and polymer resin to form uniform, low-porosity slabs.

Understanding the distinction is key for buyers and specifiers — engineered quartz provides uniform color/pattern and low maintenance; quartzite offers natural veining and heat resistance but typically requires sealing.

How is quartz made in nature?

Quartz forms by geological processes over millions of years. Key natural formation routes:

Crystallization from silica-rich fluids: In igneous or hydrothermal settings, silica-rich fluids cool and precipitate quartz crystals in veins and pockets.

Sedimentary origin (sandstone): Sand composed mostly of quartz can lithify into sandstone; deep burial + tectonic heat/pressure recrystallizes the sand into quartzite — the interlocking quartz grains produce a very hard, dense rock ideal for countertops.

Natural quartzite slabs are quarried, cut into blocks, then sawn into slabs and polished — a mechanical but comparatively lower-chemical manufacturing chain than engineered stone.

How is engineered quartz made? A step-by-step walk-through

Raw materials

Ground quartz aggregate: the bulk (often 90–95%) — sourced from silica/quartz quarries and crushed to controlled sizes for strength and appearance.

Polyester or epoxy resins: bind the quartz particles together. Modern formulations sometimes include polyester blends or polyurethane resins for better performance.

Pigments & additives: colorants, UV stabilizers, and sometimes recycled glass or mirror chips for sparkle.

Catalysts & fillers: to control cure time and mechanical properties.

Mixing & binding

Manufacturers precisely meter the ground quartz, resin, and pigments. The dry quartz is mixed with resin and additives under vacuum to reduce voids and ensure uniform coating of particles. Ratio control (quartz: resin) is critical for strength, porosity, and thermal behaviour.

Molding, vibro-compaction & curing

Most large producers use vibro-compaction or suction-compaction systems (e.g., Bretonstone process) to form slabs:

Mixed composite is placed into molds.

A vacuum removes air; vibration compacts the mix tightly around the resin.

Heat/pressure curing (autoclave or oven) turns the mix into a dense, cured slab.

Slabs are de-molded, trimmed, and prepared for finishing.

Different factories have variations: casting vs continuous pressing, vs Breton-type vibro-compression. Larger manufacturers scale using automated lines to produce consistent slab sizes and thicknesses.

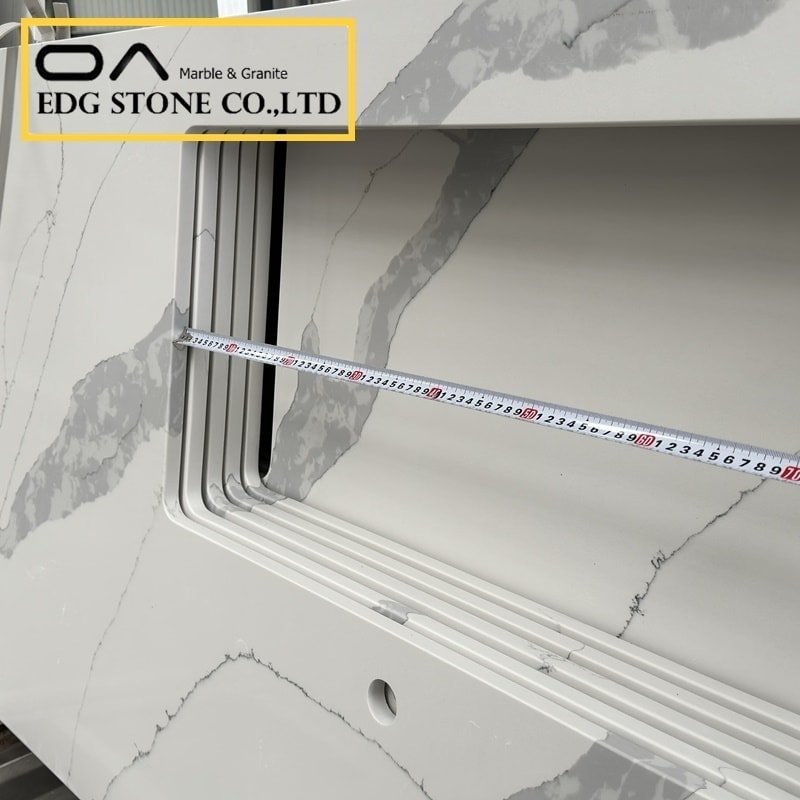

Polishing & finishing

Once cured, slabs are ground flat, edges profiled, and surfaces polished through multi-step abrasives to the required sheen (matte to high gloss). Final QC checks for flatness, color consistency, and micro-defects are performed before shipping.

How are granite countertops made? (Short comparison)

Granite is quarried as large blocks, sawn into slabs (diamond wire saws), surface ground and polished, then fabricated (cutting for sinks, edges) much like quartzite. No resin binder is added — granite is a natural stone with inherent variation and slightly higher porosity than engineered quartz (often requiring sealing).

Regulations, worker safety, and why this matters now

Respirable crystalline silica (RCS) — tiny particles generated when cutting, grinding, or dry-sawing stone — causes silicosis, lung cancer, and other diseases. Governments and regulators have increasingly tightened controls on engineered stone manufacture and use.

Australia: In December 2023, WHS ministers agreed to ban the use, supply, and manufacture of engineered stone; the ban took effect from 1 July 2024, with additional import restrictions beginning 1 January 2025 in some implementations. This policy was driven by silicosis cases linked to engineered stone work. Safe Work Australia+1

United States (OSHA): OSHA enforces respirable crystalline silica standards for construction and general industry, requiring exposure controls, respiratory protection, and training. Manufacturers and fabricators must comply with these standards when cutting or handling silica-containing materials. OSHA+1

These regulatory shifts are changing manufacturing practice, automation, and geography of production: factories invest in wet cutting, enclosed extraction, automation, and worker health programs; some jurisdictions limit or ban certain engineered stone uses entirely.

Market context & data (what the numbers say)

The global countertops market and quartz subsegment remain large and growing, but regulatory pressure and material preference shifts are reshaping demand:

The global countertops market was reported in 2024 at roughly USD 130–148 billion (different reports vary by scope), with projected growth toward 2030 driven by construction and renovation activity.

Specific quartz countertop market estimates place the quartz segment at tens of billions (USD ~85B for a broader quartz market in 2024 per some data vendors), with varying CAGR forecasts depending on the defined product scope and region.

Implication: demand remains strong, but buyers and specifiers increasingly ask about supply chain origin, factory safety practices, and recycled content, and regulated markets are accelerating demand for safer manufacturing methods and alternative materials.

Common problems with quartz countertops — causes & fixes

Heat damage/discoloration: Engineered quartz is heat-resistant but not heat-proof. Use trivets; rebuild or replace damaged sections if the resin has degraded.

Chips & impact cracks: Sharp impacts at edges or unsupported spans can chip; most fabricators can perform edge repairs with color-matched epoxy.

Staining: Engineered quartz is low-porosity; most household stains clean with mild detergent. For oil-based stains, a poultice or manufacturer-approved cleaner works.

Seams / color mismatch: Variability between slabs (different batches) can lead to visible seams — request “bookmatched” or same-lot slabs from the manufacturer/factory.

Surface haze or dull spots after installation: Often polishing or a specialized cleaner/polish restores sheen (see next section).

How to make quartz countertops shine (practical steps)

Routine cleaning: soft microfiber, pH-neutral soap, warm water. Avoid abrasive pads.

Polish for gloss: Use a manufacturer-recommended non-abrasive stone polish. Apply sparingly and buff with a clean microfibre pad.

Professional repolishing: If abrasive wear has dulled the finish, a stone fabricator can repolish the surface using progressive diamond abrasives to restore original gloss.

Avoid risky chemicals: oven cleaners, strong acids, or prolonged exposure to perfumes/cologne can harm some resin surfaces.

Problems with quartz countertops that buyers should ask about

Is the slab from the same production lot? (for color continuity)

What is the quartz: resin ratio? (affects hardness & heat behavior)

Factory safety & cutting methods: wet vs dry cutting; RCS controls.

Warranty & repair policy: what’s covered for chips, staining, or delamination?

Use manufacturer/factory/wholesale language when requesting quotes (e.g., “Request factory MOQ from manufacturer; submit RFQ for wholesale slabs”) to surface suppliers geared for trade orders.

How to make quartz slabs in Minecraft (fun short guide)

If you mean the in-game Minecraft quartz block, use Nether quartz (mined from Nether quartz ore) and craft blocks or slabs at a crafting table. For a realistic “quartz slab” aesthetic in a Minecraft build, use quartz blocks, white concrete, and custom resource packs — a fun, low-stakes way to prototype countertop layouts before ordering real slabs.

Buying considerations — manufacturer, factory & wholesale tips

Ask for SDS & composition: Safety Data Sheets show crystalline silica % and resin components.

Request factory photos & process description: wet cutting, enclosed extraction, and PPE use are good indicators.

MOQ & lead times: wholesalers and factories can offer slab pricing and color reserves if you commit to a lot MOQ.

Sample policy & shipping: insist on full-scale samples or full slab photos under consistent light; factor in shipping and crating costs.

Certifications: ISO quality systems, environmental management (ISO 14001), and documented RCS controls are pluses.

Semantic closure: How/Why/What/Options/Considerations

Why it matters: The engineered process yields consistent color, low porosity, and easy maintenance compared with many natural stones — but it raises occupational silica risks during cutting, prompting regulatory and factory-level changes.

What are the options: Choose between **natural quartzite** (unique, heat-tolerant, needs sealing) and **engineered quartz** (uniform, low maintenance). For regulated markets, select products from factories using wet cutting/enclosed extraction or consider alternative low-silica surfaces.

Considerations for buyers & specifiers: Verify silica content, request SDS, prefer factories with automated wet processes, and include warranty & repair terms in contracts. Also weigh lifecycle: recycled content/embodied carbon vs durability and replacement cycles.

Trend & regulation note: Expect more regions to adopt stricter silica rules or targeted bans on high-silica engineered stone; manufacturers will accelerate safer production methods and alternative binder technologies.

FAQ — 5 Google hot search style questions (original text + structured JSON-LD)

1. How is a quartz countertop made?

Answer: Engineered quartz countertops are made by combining crushed quartz with polymer resin and pigments, compacting the blend under vacuum/vibration, curing the slab, and then polishing to the desired finish. Quality depends on quartz ratio, resin type, and factory process.

2. How is quartz made in nature?

Answer: Natural quartz forms from silica-rich fluids in igneous/hydrothermal settings or by lithification and metamorphism of quartz-rich sand into quartzite over geological time.

3. How is engineered quartz made in a factory?

Answer: Factories measure raw quartz aggregate and resin, mix under vacuum, form slabs (vibro/compaction), cure, trim, and polish. Modern factories emphasize wet cutting and enclosed extraction to limit respirable crystalline silica.

4. How to make quartz countertops shine?

Answer: Use pH-neutral cleaners and microfiber cloths for daily care; apply manufacturer-approved non-abrasive polish as needed; for severe dulling, use a stone fabricator to repolish with diamond abrasives.

5. What are the problems with quartz countertops?

Answer: Common issues include heat damage, chips, seam visibility, and rare staining. Proper fabrication, installation, and care minimize most problems.

Long-tail keywords, 50 SEO tags

Long-tail purchase-intent keywords (3–5 examples):

how is engineered quartz made manufacturer

quartz slab factory wholesale price

buy quartz countertops from manufacturer bulk

quartz countertop slabs wholesale factory direct

calacatta quartz slab manufacturer wholesale

50 SEO tags (mix of high-intent & informational):

how quartz stone is made,how is quartz countertops made,engineered quartz manufacturing,quartz slab factory,quartz manufacturer wholesale,buy quartz slabs factory direct,how is quartz made in nature,quartzite vs engineered quartz,how to make quartz countertops shine,problems with quartz countertops,quartz countertop price per square foot,calacatta quartz manufacturer,quartz countertop manufacturing process,quartz slab production steps,quartz countertop care,respirable crystalline silica safety,engineered stone ban Australia,granite vs quartz price,quartz countertop warranty,quartz factory MOQ,quartz slab polish techniques,quartz countertop installation issues,quartz countertop repair,sustainable quartz countertops,recycled quartz slabs,quartz countertop quality control,quartz slab resin ratio,quartz slab supplier,wholesale quartz countertops,quartz countertops factory tour,how quartzite is formed,quartz countertop finishing,quartz countertop maintenance tips,quartz countertop trends 2025,quartz sink compatibility,quartz slab thickness options,engineered quartz health risks,quartz countertop certifications,quartz countertop vs granite,quartz countertop edge profiles,quartz slab shipping crating,quartz countertop sample policy,buy quartz countertops online wholesale,stone countertop manufacturer,quartz countertops for kitchens,quartz countertops for bathrooms,calacatta quartz slab wholesale,quartz slab import rules,how to choose quartz slab,quartz countertop cleaning products.