Introduction

Table of Contents

Toggle- Introduction

- What is labradorite? (short primer)

- Price breakdown: slab, price per sq ft, and installed cost

- What drives labradorite pricing? (key factors)

- Labradorite durability — is labradorite suitable for kitchens?

- Where to buy Labradorite countertops (sourcing paths)

- Regulations & industry trends that affect cost, supply, and safety

- Buying checklist & negotiation tips

- 3–5 long-tail keyword expansions (purchase-intent versions)

- 50 SEO tags

- FAQ — Top 5 Google-style questions (short answers)

- Semantic Closed-Loop Summary: How / Why / What / Options / Considerations

Labradorite — prized for its iridescent “labradorescence” — has moved from museum countertop fantasy to an available (but still premium) surfacing option. This guide explains how much labradorite countertops cost, why prices vary so widely, where to buy them, how durable they are, and how changing safety and import rules in key markets are reshaping supply and fabrication costs.

What is labradorite? (short primer)

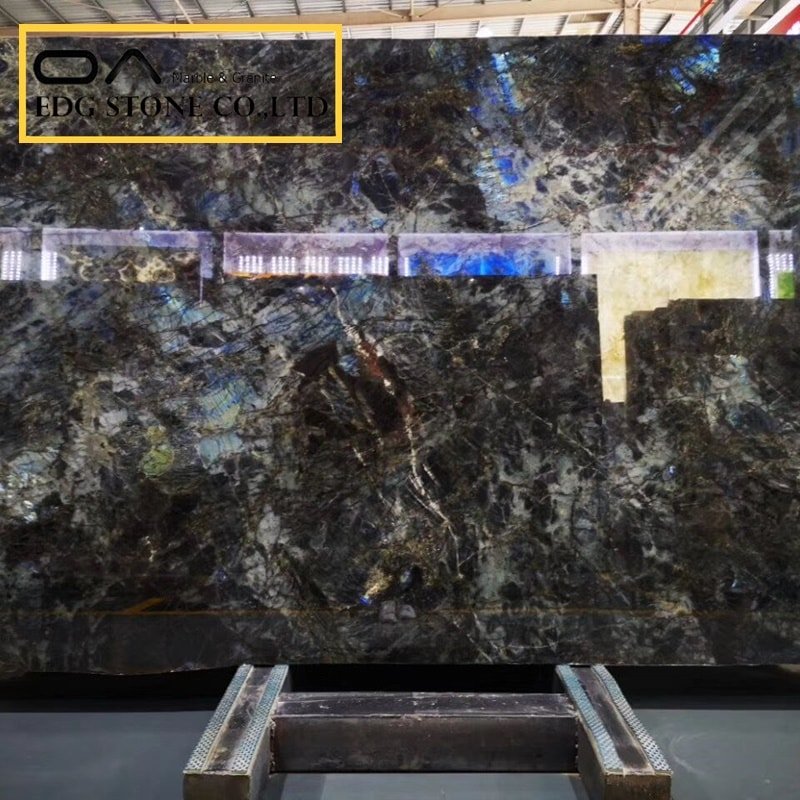

Labradorite is a feldspar mineral noted for a play of color (iridescence) when light reflects off microscopic internal structures. In the surfacing market, you’ll see it sold both as “labradorite slab” / “labradorite blue granite / lemurian blue” and as custom gem- or semi-precious-inlaid slabs. It is used for countertops, backsplashes, and statement islands where the shimmering effect is wanted. Some suppliers also market “moonstone” or amethyst-surface alternatives as related gemstone-slab categories; these are niche, decorative alternatives rather than commodity stones.

Price breakdown: slab, price per sq ft, and installed cost

Slab price (raw slab)

Higher-grade labradorite slabs—especially exotic Madagascar “blue” varieties—are commonly listed in premium ranges. Industry supplier listings and trade pages report slab-level pricing frequently between roughly USD $100–$200 per square foot for quality gem-like slabs (20–30 mm), though lower-grade slabs can be found for less, and extremely rare specimens can be higher.

Retail / installed price (per square foot, finished)

When templating, fabricating, and installing, retail prices for a finished labradorite countertop can rise significantly. Published consumer-cost guides and estimator pages place installed costs often in the several-hundred-dollar-per-square-foot bracket (examples showing $200–$300/ft² installed for higher-end projects), with an entire kitchen commonly reaching $6,000–$12,000+ or more depending on slab usage and fabrication detail. These totals include fabrication complexity, edging, seams, cutouts, and installation labor.

Wide ranges are normal — prices vary with slab yield (how many square feet per slab), bookmatching or complex patterning, shipping & import fees, and local fabrication labor rates (which can increase in markets enforcing stricter safety controls).

Quick pricing rule of thumb: expect slab cost to be a meaningful baseline but installed cost to be roughly 2–4× the slab-per-square-foot number depending on complexity and local labor.

(Price references above summarize multiple supplier and buyer-facing sources.)

What drives labradorite pricing? (key factors)

Rarity & origin — Certain Madagascar and South American varieties (marketed as “Labradorite Blue” or “Lemurian Blue”) are scarcer and command higher unit costs.

Visual quality & color play — Intense, broad-surface iridescence with minimal veining yields premium pricing (bookmatched pairs are extra).

Slab size & yield — Larger, unbroken slabs that allow fewer seams are worth more per square foot.

Thickness & finish — 30 mm or specially honed/polished finishes cost more.

Fabrication complexity — Integrated sinks, waterfall edges, heavy cutouts, and bookmatching increase fabrication time and cost.

Logistics & import duties — Exotic origins plus international freight and customs add to landed cost.

Health & compliance costs — Safer cutting controls, dust-abatement measures, and compliance with silica-related rules can increase fabricator overhead and therefore customer prices (see regulatory section).

Supply channel — Buying direct from quarries/manufacturers or in bulk (wholesale/factory) will typically lower per-unit slab price versus retail distributors.

Labradorite durability — is labradorite suitable for kitchens?

Hardness & scratch resistance: Labradorite (as a feldspar-rich natural stone or trade-labeled “labradorite granite”) behaves like other hard natural stones: it is generally scratch-resistant for normal kitchen use but not scratch-proof. Use cutting boards and avoid abrasive scouring.

Heat resistance: Natural stone tolerates moderate stove-top heat; however, sudden thermal shock should be avoided.

Porosity & sealing: Some labradorite slabs are more porous than granite—regular sealing (frequency depends on porosity) protects against staining.

Maintenance: Clean with pH-neutral stone cleaner; reseal per manufacturer/fabricator guidance (often annually or every few years, depending on use).

Lifespan: With proper care, natural stone countertops, including labradorite, can last decades and often increase home value due to their uniqueness and aesthetics.

Bottom line: Labradorite is durable enough for kitchen and bath use when finished and installed by experienced fabricators and cared for correctly—its selling point is aesthetic drama rather than becoming the absolute toughest surface available.

Where to buy Labradorite countertops (sourcing paths)

Direct quarry/importer/slab manufacturers — For the best slab pricing and volume buys, contact specialized gemstone-slab makers and exporters in China, Brazil, India, and Madagascar. Many trade suppliers list Labradorite slabs and can ship internationally. Examples of slab suppliers and their price pages show active listings.

Specialty stone warehouses & distributors — US/Europe-based warehouses sometimes stock labradorite; they supply fabricators and retail customers. Search “labradorite slab + [your city/region]” or contact local stone yards.

Custom fabricators & stone shops — Local fabricators often source exotic slabs through distributors; they arrange templating and installation.

Online marketplaces / B2B portals — Alibaba, StoneContact, and specialized stone portals list slabs and wholesale/ODM options. Beware of photos — always request physical slab photos and dimensions.

Manufacturer / factory purchase (wholesale) — If you’re a trade buyer, ask for manufacturer quotes (MOQ, slab grade, export cost). Buying multiple slabs reduces per-unit freight and handling margins.

Tip: Ask sellers for exact slab dimensions, thickness, origin, finish, and high-resolution photos (including backlit images to evaluate labradorescence). Request an explicit return/damage policy for shipped slabs.

Regulations & industry trends that affect cost, supply, and safety

In recent years, worker safety concerns around respirable crystalline silica (RCS) and engineered stone have driven major regulatory changes — these affect fabrication costs and sometimes the market positioning of natural stone.

Key regulatory highlights:

U.S. OSHA Respirable Crystalline Silica Standard — OSHA’s silica standards require fabricators to limit worker exposures and implement controls (wet cutting, local exhaust ventilation, respirators, training), which raises compliance costs for shops that cut slabs on-site. The standard and guidance information are available from OSHA. 职业安全与健康管理局

Australia: engineered stone prohibitions and import restrictions — Australia moved to ban the use/supply/manufacture of engineered stone in 2024 and has import restrictions coming into effect for certain dates (e.g., import bans beginning in 2025 in some rules), in response to silicosis outbreaks among engineered-stone workers. This has pushed buyers toward natural stone slabs in that market and increased demand for safe fabrication.

What this means for price & supply:

Fabricators investing in compliant cutting systems, dust collection, and training pass those costs to buyers; smaller shops that cannot meet rules may reduce capacity, tightening local supply of exotic slabs and increasing lead times.

Markets that limit or ban engineered quartz have seen a rise in demand for natural stones (including labradorite), sometimes increasing prices due to demand/supply shifts.

Buying checklist & negotiation tips

Ask for slab photos (both lit and backlit) and dimensions before purchase.

Confirm thickness & finish (20 mm vs. 30 mm will affect price).

Request an itemized quote separating slab cost, fabrication, edge treatments, cutouts, sink undermount, template & install labor.

Check fabricator compliance: ask how they control silica dust and whether the price includes OSHA/industry-mandated safety measures (this affects long-term warranty & worker safety).

Consider shipping & customs: exotic slabs can add weeks of lead time and extra cost—factor this in.

Negotiate for volume or repeat-order discounts if buying multiple slabs or specifying as a developer.

3–5 long-tail keyword expansions (purchase-intent versions)

labradorite countertop slab manufacturer wholesale

buy labradorite countertops factory direct

labradorite blue granite slab price per square foot wholesale

labradorite countertops near me supplier and installer

labradorite countertop wholesale factory MOQ and shipping

50 SEO tags

labradorite countertop price,labradorite countertop cost,labradorite slab price,labradorite price per square foot,labradorite countertops near me,labradorite granite countertop,labradorite blue granite,lemurian blue slab price,buy labradorite countertop,labradorite slab supplier,labradorite wholesale factory,labradorite manufacturer,labradorite countertop durability,how much do labradorite countertops cost,labradorite countertop installation cost,labradorite countertop price per sq ft installed,labradorite slab for sale,labradorite tabletop slab,labradorite vs quartz cost,labradorite maintenance,labradorite sealing instructions,labradorite countertop stone care,labradorite kitchen island cost,labradorite bookmatched slab,rare labradorite slab price,labradorite export supplier,labradorite ecommerce slab,labradorite countertop retailer,labradorite stone supplier China,labradorite Madagascar slab,labradorite slab shipping cost,labradorite countertop quote,labradorite cost comparison,labradorite countertop value for money,labradorite countertop hardiness,labradorite counter top cost estimator,labradorite statement island price,labradorite remnant price,labradorite slab factory direct,labradorite countertop wholesale price,labradorite gemstone slab cost,moonstone countertop alternative,amethyst countertop cost,labradorite countertop supplier near me,labradorite slab exporters,labradorite countertop lead time,labradorite cost per slab,labradorite slab thickness price,labradorite countertop installation tips,labradorite countertop environmental impact.

FAQ — Top 5 Google-style questions (short answers)

How much do labradorite countertops cost per square foot?

Prices vary widely; slab-level listings for quality labradorite commonly range around $100–$200/ft², while finished installed costs for projects can fall into the $200–$300+/ft² range depending on fabrication.Is labradorite durable enough for a kitchen countertop?

Yes—labradorite behaves like other natural hard stones: scratch-resistant for normal use, heat-tolerant with care, and typically requires periodic sealing depending on porosity.Where can I buy Labradorite slabs?

You can buy through specialized stone suppliers, slab warehouses, B2B portals (stone exporters/manufacturers), or local fabricators who import exotic slabs. Request slab photos and origin details.Does labradorite cost more than granite or engineered quartz?

Labradorite is often priced at a premium relative to commodity granites because of its rarity and visual effect; installed quartz prices vary widely and are influenced by brand and composition. Expect labradorite to be in the higher tier for exotic natural stone.Are there regulatory or safety considerations when buying or fabricating Labradorite countertops?

Yes. Fabrication produces dust that can contain crystalline silica; fabricators must follow local occupational-safety rules (e.g., OSHA in the U.S.), and some jurisdictions (like Australia) have recently restricted engineered stone due to silica risks — these rules affect fabrication costs and processes. 职业安全与健康管理局+1

Semantic closed-loop content block

Semantic Closed-Loop Summary: How / Why / What / Options / Considerations

How: Labradorite countertops are quarried as large slabs, cut to size, finished (polished/honed), templated to the project, fabricated (edges, cutouts), and installed. Fabrication must use wet cutting or dust-extraction equipment to control respirable crystalline silica when present.

Why: Buyers choose labradorite for visual uniqueness—iridescence, depth, and one-of-a-kind bookmatched patterns—making it a statement surface that often yields higher perceived value in residential and boutique commercial projects.

What: Costs include slab purchase, freight/import, fabrication and template labor, installation, and safety/compliance overhead for fabricators. Market prices range, but premium slabs and complex installs are significantly more expensive than commodity stone.

Budget-conscious: Use remnants or smaller countertop runs, keep seams visible, opt for 20 mm thickness.

Mid-range: Select stocked slabs from a distributor, moderate edge profiles, standard undermount sink.

High-end: Bookmatched island faces, 30 mm full-wraps, waterfall edges, custom lighting/backlighting for maximum effect.

Considerations (detailed)**:

Regulatory: Confirm fabricator silica controls and local regulations; engineered-stone bans in some regions may alter availability and price dynamics.

Sourcing: Request exact slab photos, origin, and transport timeline.

Durability & Care: Seal as needed; use soft cleaners and cutting boards to protect the finish.