Quality Control

About EDG Stone Quality Control Departments

Importance of Quality Inspection in Stone Products

Ensuring quality at every stage of stone product manufacturing is critical to meeting international standards and customer expectations. Rigorous quality control minimizes defects, enhances aesthetics, and guarantees durability. At EDG Stone, our dedicated QC team oversees each process to deliver products that perfectly meet market demands, especially in the European and American markets.

About EDG Stone Quality Control Departments

Raw Stone (Rough Stone) Selection

Assessment of Natural Qualities:

The process begins with selecting high-quality rough stone from quarries. Our experts evaluate color consistency, texture, and structural integrity to ensure that only the best raw materials are used.Geological Analysis:

Each stone block is examined for mineral composition and durability to ensure it meets the required technical specifications.

About EDG Stone Quality Control Departments

Large Slab Selection and Cutting

Slab Selection:

Experts choose slabs based on the grain, pattern, and minimal visible imperfections to achieve a consistent aesthetic appeal.Initial Cutting:

Using advanced diamond wire saws, the rough stone is cut into large slabs with precision, ensuring minimal waste and optimal use of material.

About EDG Stone Quality Control Departments

CNC Engraving & Waterjet Cutting

Precision Carving:

CNC (Computer Numerical Control) machines are used to engrave intricate designs and patterns on stone surfaces. This step is crucial for achieving detailed and consistent decorative elements.Quality Verification:

Every engraved piece undergoes strict dimensional and quality checks to maintain uniformity across the product line.High-Precision Cutting:

Waterjet technology provides precise and clean cuts without generating heat, thus preserving the stone’s natural properties.Customization:

This method is used for creating customized shapes and intricate designs, ensuring that every cut meets the design requirements.

About EDG Stone Quality Control Departments

Professional Hand Processing

Skilled Craftsmanship:

Experienced artisans perform delicate hand processing to refine edges and details that machines cannot achieve. This step adds a unique touch to each product.

Surface Refinement:

Hand polishing and detailed adjustments ensure that the natural beauty of the stone is fully realized.Edge Profiling:

Stone edges are processed using specialized machinery and hand tools to achieve smooth, uniform edges that enhance both aesthetics and safety.Durability Enhancement:

Proper edge processing also improves the stone’s resistance to chipping and damage during handling and installation.

About EDG Stone Quality Control Departments

Stone With Different Surface Finishing

Polished and Matte Finishes

Polishing Process:

Advanced polishing techniques create a high-gloss finish that highlights the natural veining and colors of the stone. The polished surface is tested for uniform shine and clarity.Matte Finishing:

For clients preferring a more subtle, non-reflective look, matte finishes are applied. These finishes are carefully controlled to achieve the desired texture without compromising quality.

Specialized Surface Treatments

Antique Finish:

Through controlled abrasion and finishing techniques, an antique look is achieved that gives the stone a classic, timeless appearance.Acid-Etched Finish:

Acid washing is used to create a unique texture on the stone surface. This process requires careful control to ensure consistent results and durability.

About EDG Stone Quality Control Departments

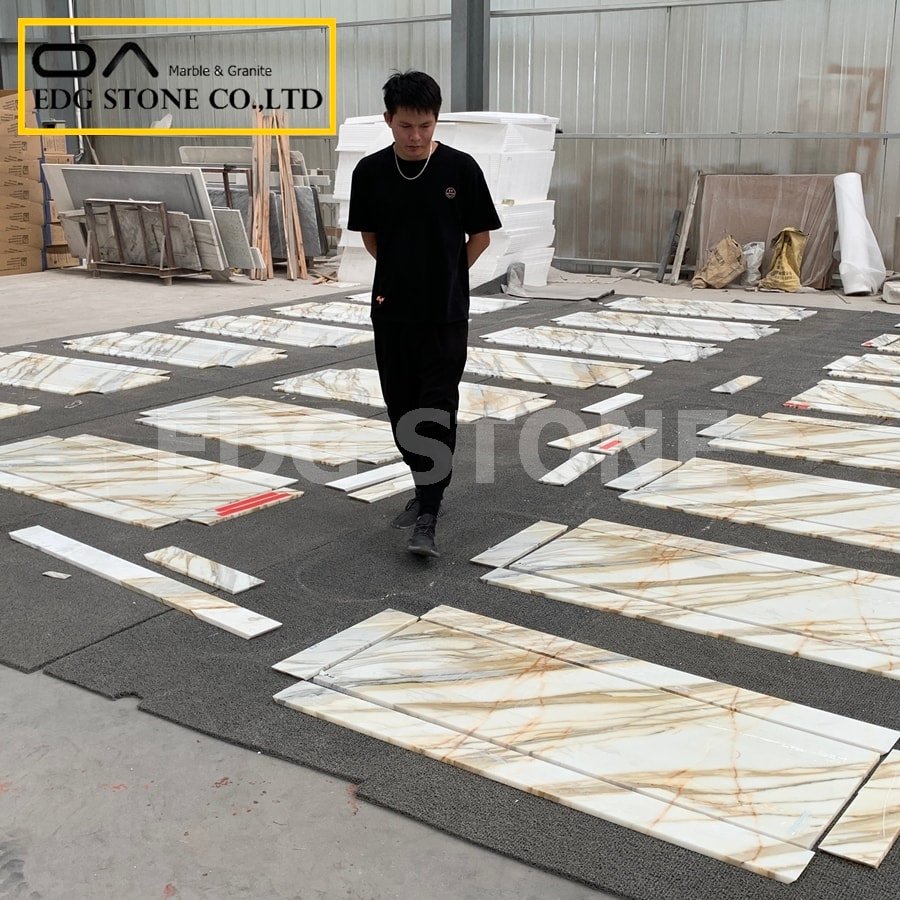

Stone Layout and Pattern Design

Design and Planning:

Before the final assembly, stone slabs are meticulously arranged to form aesthetically pleasing patterns. Layout planning considers color variations, grain direction, and overall design harmony.Quality Checks:

The layout process includes verifying that patterns align perfectly and that there are no visible seams or mismatches.

About EDG Stone Quality Control Departments

Packaging By European and American Markets Standard

Custom Packaging Standards:

Our packaging process meets stringent European and American market requirements. Each stone product is carefully packaged to protect it during transit.Material and Design:

High-quality, durable packaging materials are used. The packaging design not only safeguards the product but also reflects the premium quality of EDG Stone’s offerings.Labeling and Documentation:

Every package includes detailed documentation and quality certificates, ensuring traceability and customer confidence.

About EDG Stone Quality Control Departments

Final Container Loading

Secure Container Loading:

The final step involves loading the packaged stone products into containers. Our team follows international shipping standards to ensure safe and damage-free transit.Inspection Prior to Shipping:

Before sealing, a final quality inspection is conducted to ensure that all products meet the highest standards. The container is then securely sealed and labeled for shipment.

EDG Stone’s Professional QC Inspection Team

At every stage of the production process, EDG Stone’s expert Quality Control (QC) team plays a crucial role. Our QC specialists conduct rigorous inspections and tests—from raw stone selection to final container loading—to ensure that every product is perfect. Their commitment to excellence guarantees that all stone products not only meet but exceed international quality standards, ensuring our customers receive nothing less than perfection.

56+

Export Countries

125+

Collaegues & Counting

195+

Successfully Project

35+

Year of experience

The Team

Our Experts

Richard Xiong

Export Director

John Zhang

Product Director

William Pan

QC Director

William Pan

QC Director

Sustainability

Committed To Produce & Supply The Best Stone Products

We have been focusing on quarrying, manufacturing, and exporting high-quality products worldwide, including Granite, Marble, Calacatta gold marble, Onyx, calacatta quartz slab, Quartz, Artificial Marble, Basalt, volakas white marble, agate slabs countertops, Travertine, Limestone, Bluestone, Slate, Sandstone, Composite Brick, etc.

We Follow Best Practices

EDG has been devoted to creative efforts and continuing the improvements. Based on the high quality, we expand our products category and cut down the cost. we try our best to guarantee any exact customer requirement. we believe that with our experienced working team and professional management, you would find us to a reliable business partner.

- Sustainablility

- Project On Time

- Modern Technology

- Latest Designs