Onyx Countertops

- Home

- >

- Onyx Countertops

Backlit Onyx Countertops

Harness the mesmerizing beauty of light with EDG Stone’s custom backlit onyx countertops. As China’s leading onyx countertop manufacturer, we engineer panels to optimum thinness, enhancing translucency without compromising strength, so LED illumination reveals the stone’s dramatic patterns. Our in-house design team collaborates with you on panel thickness, edge detailing, and lighting layouts, guaranteeing seamless integration of stones and light sources. Precision routing and adhesive lamination ensure reliable thermal performance and structural stability for years of glowing ambiance. Whether for a hotel bar, luxury kitchen island, or statement bathroom vanity, EDG Stone’s backlit onyx delivers a one-of-a-kind, high-impact installation that elevates any interior to gallery-worthy brilliance.

Natural Onyx Countertops Manufacturer in China

EDG Stone’s onyx countertops extend well beyond traditional kitchen surfaces: they adorn bar tops, bathroom vanities, reception desks, accent walls, and even custom furniture. We offer specialized thin-cut panels ideal for backlit installations in hospitality lobbies and retail feature walls that demand visual drama. Our custom fabrication services include precise sink and appliance cutouts, mitered corners for waterfall edges, and integrated inlays of metal or glass. Structural reinforcement options—such as resin backing and hidden steel supports—allow safe application over cantilevers or floating shelves. With EDG Stone’s tailored solutions, onyx becomes a versatile design material that enhances any commercial or residential project with its natural elegance.

EDG Stone / Luxury Kitchen & Bathroom Design With Onyx

A variety of stone options to meet your high-end needs

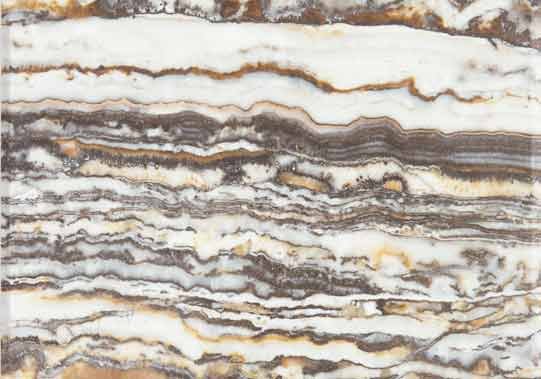

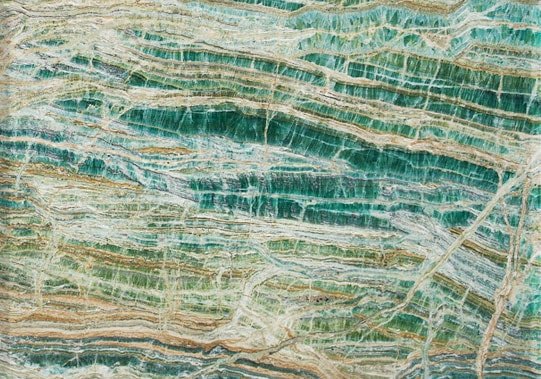

Onyx Countertops deliver a spectrum of premium stone choices tailored for luxury interiors. From classic white and honey onyx to rare blue and green varieties, each slab exhibits unique banding, translucence, and color saturation. Our curated selection includes thick-cut panels for dramatic backlit installations and thinner veneers for accent walls or cabinetry facades. Clients can choose polished, honed, or leathered finishes to complement modern or traditional schemes. Rigorous quality control ensures every slab meets stringent standards for structural integrity, color consistency, and light transmission. Whether you seek a statement kitchen island or an elegant hotel lobby reception, Onyx Countertops offer unparalleled versatility and sophistication.

Perfect fusion of modern design and traditional craftsmanship

Onyx Countertops epitomize the marriage of cutting-edge fabrication technology and time-honored stoneworking techniques. Advanced CNC routers precisely shape each panel to within ±0.5 mm tolerances, while our master artisans hand-finish edges—be they streamlined eased profiles or intricate ogee details. Digital templating guarantees perfect alignment with cabinetry and fixtures, and expertly executed mitered seams create seamless transitions. This blend of modern automation and bespoke hand polishing elevates the natural beauty of onyx, highlighting its inherent translucence and veining. The result is a surface that meets rigorous performance criteria—resistance to scratches, stains, and heat—while exuding the warmth and character of artisanal craftsmanship.

Unique functionality and space optimization

Onyx Countertops offer exceptional functionality and intelligent space utilization in any design project. Thin-profile slabs allow for sleek waterfall edges that visually enlarge compact kitchens without sacrificing strength. Integrated recesses for sinks, cooktops, and utensil storage streamline workflows and maintain clean sightlines. Backlit onyx panels transform under-cabinet areas and bar fronts into luminous focal points that merge form and utility. Innovative templates accommodate built-in LED channels and concealed wire management for appliances and lighting. This combination of custom fabrication and strategic detailing optimizes every square inch, ensuring your space feels more open, organized, and tailored to the realities of daily life—all while showcasing the luminous beauty of onyx.

Sturdy and durable, long-term companionship

Despite its delicate appearance, onyx is reinforced through state-of-the-art resin impregnation and precision polishing techniques to produce robust Onyx Countertops built for longevity. The naturally hard calcite structure gains additional tensile strength from polymer binders, reducing vulnerability to chipping and cracking. Non-porous finishes repel moisture, bacteria, and stains, eliminating the need for frequent sealing and simplifying maintenance. Structural reinforcements—such as steel-backed laminations for cantilevered islands—ensure stability under heavy loads. Over years of daily use, Onyx Countertops retain their translucent glow and vivid veining with minimal care. This reliable durability makes onyx an enduring, elegant companion for kitchens, bathrooms, and hospitality spaces alike.

Onyx Countertop Applications

EDG Stone’s onyx countertops extend well beyond traditional kitchen surfaces: they adorn bar tops, bathroom vanities, reception desks, accent walls, and even custom furniture. We offer specialized thin-cut panels ideal for backlit installations in hospitality lobbies and retail feature walls that demand visual drama. Our custom fabrication services include precise sink and appliance cutouts, mitered corners for waterfall edges, and integrated inlays of metal or glass. Structural reinforcement options—such as resin backing and hidden steel supports—allow safe application over cantilevers or floating shelves. With EDG Stone’s tailored solutions, onyx becomes a versatile design material that enhances any commercial or residential project with its natural elegance.

Onyx Countertop Care & Maintenance

Best Onyx Countertop Material for Kitchen

Selecting the best onyx countertop material for kitchens involves balancing translucence, pattern, and durability. Warm honey onyx offers a soft amber backlit glow, while classic white onyx provides a neutral canvas for diverse décor styles. Green and blue onyx varieties deliver bold, jewel-tone statements, ideal for focal islands. For active cooking spaces, choose slabs with denser calcite bands reinforced by resin impregnation to resist chipping. Polished finishes maximize light reflection, enhancing brightness, whereas leathered textures conceal minor wear from daily use. Precise CNC-machined edges and low-profile waterfall installations ensure seamless integration. With careful selection of onyx type and finish, kitchens become both functional and artful showcases of natural stone beauty.

Onyx Countertop Cost

Budgeting for Onyx Countertops requires understanding material quality, fabrication complexity, and installation scope. Base material costs range from $80 to $200 per square foot, depending on onyx rarity, translucence, and slab dimensions. Custom edge profiles, integrated backlighting channels, and precision cutouts for sinks or cooktops incur additional fabrication fees. Installation expenses factor in specialized mounting brackets, reinforced supports for waterfall edges, and coordination of LED wiring. Shipping from the quarry to the fabrication facility and then to the site also influences the total cost. While onyx represents a premium investment versus conventional stones, its transformative visual impact and singular translucence can significantly elevate a project’s luxury appeal and long-term value proposition.

Onyx Stone Proerties

Onyx Countertops are prized for their distinctive banded calcite formation, which delivers exceptional translucency and rich color variation. With a Mohs hardness of 3–4, pure onyx is softer than quartzite or granite, but modern resin-impregnation processes enhance its surface strength and durability. Light transmission rates of up to 20% enable stunning backlit applications, while porosity levels below 0.5% reduce susceptibility to staining. Thermal expansion coefficients are carefully controlled to prevent warping under normal temperature fluctuations. Each slab undergoes rigorous inspection for thickness tolerance (±0.5 mm), uniform vein alignment, and structural integrity. These properties make onyx a uniquely luminous, tactile, and visually striking material for high-end surfacing.

Onyx Countertop Price Cost

The investment in Onyx Countertops reflects the rarity and craftsmanship inherent in each slab. Premium onyx varieties command higher material costs per square foot, typically ranging from $80 to $200, influenced by color rarity, translucence, and thickness. Fabrication adds precision cutting, edge profiling, and optional backlighting channels to the final price. Installation factors—such as accessibility, substrate reinforcement, and integrated lighting infrastructure—also contribute to the overall budget. While onyx may carry a higher upfront cost than granite or quartz, its unmatched aesthetic impact and customizable translucence often justify the premium. When evaluating quotes, consider long-term value: Onyx’s durability and timeless elegance can enhance property appreciation and design prestige.

Onyx Countertop Cost & Installation

EDG Stone delivers transparent cost estimates for onyx countertop projects, reflecting slab grade, thickness, finish, and backlighting requirements. While premium onyx varieties command higher material costs, our factory-direct pricing from China balances quality and value, and our volume discounts make larger projects more economical. Installation is handled by our network of trained fabricators who follow precise templating, leveling, and adhesive techniques to secure each panel with seamless joins. For backlit applications, we coordinate lighting fixtures and wiring with installers to guarantee uniform illumination. EDG Stone’s end-to-end service—from quotation through post-install support—ensures predictable budgets and flawless implementation.

Onyx Countertop Types

EDG Stone’s diverse onyx countertop offerings include classic calcite-based onyx, honey onyx with warm amber hues, green onyx featuring mossy veining, and rare blue onyx that delivers a striking focal point. Each type exhibits distinct translucency levels and crystal structures, which we quantify in our technical datasheets. Clients can choose from thick slabs for pronounced depth or thin-cut panels optimized for backlighting. We also offer bookmatched pairs for mirror-image vein patterns, ideal for waterfall-edge islands or symmetrical feature walls. Regardless of selection, EDG Stone’s precision fabrication and hand-polishing techniques guarantee consistent thickness, uniform finish, and perfect vein alignment for every onyx variety.

Onyx Countertop Vs. Other Materials

When comparing onyx countertops to granite, marble, or engineered quartz, EDG Stone highlights onyx’s unparalleled translucence and natural veining complexity. Unlike opaque materials, backlit onyx reveals an ethereal glow, creating dramatic visual statements. Though slightly softer than quartz or granite, our onyx panels are reinforced with high-strength resins to resist chipping. Onyx’s unique patterns cannot be replicated in engineered surfaces, offering exclusive, one-of-a-kind installations. With proper maintenance, onyx rivals the longevity of other stones while delivering a level of natural artistry unmatched by man-made composites. EDG Stone’s expertise ensures every client enjoys the distinctive allure of onyx with performance that stands up to daily use.

Onyx Slab Properties & Characteristics

EDG Stone’s onyx slabs are characterized by their banded calcite structure, exceptional translucency, and wide color palette, ranging from ivory whites to deep emeralds. With a Mohs hardness of 3–4, pure onyx is softer than quartzite or granite, but our factory-developed resin impregnations enhance surface strength and reduce porosity. Light transmission rates up to 20% make these slabs ideal for backlit applications. Slab thickness tolerances are held within ±0.5 mm to ensure accurate installation, and each piece undergoes thermal and moisture resistance testing. All onyx panels are inspected and certified for use in residential, hospitality, and retail environments, combining natural beauty with engineered performance.

Frequently asked Questions

What is your current price per square foot for Onyx Countertops?

Our standard price for polished Onyx Countertops starts at $75 per square foot, with custom finishes and edge profiles priced accordingly.

What is the minimum order quantity for Onyx Countertops?

The minimum order for Onyx Countertops is 50 square feet to ensure efficient slab utilization.

What lead time do you require to manufacture and ship Onyx Countertops?

Typical lead time for Onyx Countertops is 4–6 weeks from purchase order confirmation to delivery.

Do you offer custom edge profiles for Onyx Countertops?

Yes, we provide a full range of edge profiles—eased, beveled, ogee, waterfall—for Onyx Countertops at no additional tooling charge.

What thicknesses are available for Onyx Countertops?

We stock Onyx Countertops in 2 cm and 3 cm thicknesses; custom thicknesses can be produced upon request.

What types of Onyx Countertops finishes do you provide?

We offer polished, honed, leathered, and backlit finishes for Onyx Countertops to suit various design applications.

Can you supply Onyx Countertops with integrated sinks or cutouts?

Absolutely—our fabrication includes precise CNC cutouts for sinks, cooktops, and faucets in Onyx Countertops.

What is the country of origin for your Onyx Countertops?

Our Onyx Countertops are quarried in Pakistan and Brazil, then fabricated in our ISO-certified facility.

Do you provide on-site templating and installation services for Onyx Countertops?

Yes, we offer turnkey templating and installation for Onyx Countertops nationwide through our certified installers.

How are Onyx Countertops packaged for export?

Onyx Countertops are created in reinforced wooden A-frames with foam padding and secured with banding for safe export.

How are Onyx Countertops packaged for export?

Onyx Countertops are created in reinforced wooden A-frames with foam padding and secured with banding for safe export.

What warranty do you offer on Onyx Countertops?

We provide a 1-year limited warranty covering material defects and fabrication workmanship on all Onyx Countertops.

Can you provide samples of Onyx Countertops before placing a bulk order?

Yes, we ship 4″×4″ polished samples of Onyx Countertops free of charge (customer covers shipping).

What payment terms do you require for Onyx Countertops orders?

Our standard payment terms for Onyx Countertops are 30% deposit upon order and 70% balance before shipment.

Do you offer volume discounts for large Onyx Countertops orders?

Yes, orders above 500 square feet of Onyx Countertops qualify for tiered discounts up to 15%.

What quality certifications do your Onyx Countertops meet?

Our Onyx Countertops comply with ANSI/NSF standards and carry GREENGUARD Gold certification for low VOC emissions.

Can you provide technical data sheets for your Onyx Countertops?

Upon request, we supply detailed datasheets including physical properties, chemical resistance, and maintenance guidelines for Onyx Countertops.

Do you offer CNC engraving or inlays on Onyx Countertops?

Yes, we can create custom CNC-engraved logos, patterns, or metal inlays on Onyx Countertops per your design files.

Are there eco-friendly or recycled options for Onyx Countertops?

We offer Onyx Countertops with up to 30% recycled onyx content and use water recycling in our fabrication process.

What is the average yield from a 120″×72″ slab of Onyx Countertops?

A standard 3 cm slab yields approximately 40–45 square feet of usable Onyx Countertops, depending on layout.

How should Onyx Countertops be maintained to preserve their finish?

Clean daily with a pH-neutral stone cleaner, avoid acidic or abrasive agents, and reseal your Onyx Countertops every 12–18 months.

Contact Us

- Email: info@edgstone.com

- Phone: 008618759566040

- Whatsapp: 008618759566040