Is printed quartz cheaper?

Table of Contents

Toggle- Is printed quartz cheaper?

- What do we mean by “printed quartz”

- Short answer: Is printed quartz cheaper?

- Pricing context — typical quartz cost ranges (2024–2025 market snapshot)

- Why printed quartz costs more — the cost drivers

- What looks like quartz but is cheaper?

- Is printed quartz cheaper than natural marble or granite?

- When printed quartz is worth the premium

- Procurement & RFQ checklist for printed quartz buyers

- Maintenance & durability — printed vs non-printed quartz

- Regulation & safety — why this matters to buyers

- Quick cost examples & how to compare quotes

- FAQ — Google hot-search style (visible Q&A)

- Semantic Closure — How / Why / What / Options / Considerations

- Focus keyword + 50 SEO tags

Quick Summary: Printed quartz (aka digital-print or full-body printed engineered quartz) usually costs **slightly more** than a standard engineered quartz slab because of extra printing steps and quality control — but it’s often **cheaper than high-end natural stones**. Typical installed quartz costs range roughly **$50–$120/ft²** (brand, finish, and fabrication greatly affect price). Porcelain and some sintered-stone brands can compete on price and outperform quartz on heat/UV resistance. Buyers should weigh visual value (bookmatching, edge continuity) against cost, ask for slab-level pricing and sample approvals, and require fabricator silica-safety documentation in RFQs.

Is printed quartz cheaper?

A practical, data-backed guide for homeowners, designers, specifiers, and procurement teams — covering definitions, pricing, comparisons with alternatives, when it’s worth the premium, procurement/RFQ wording, maintenance, and regulatory considerations (silica & workplace safety).

What do we mean by “printed quartz”

“Printed quartz” is not a new stone — it refers to engineered quartz (the resin-bonded slabs made mostly of crushed quartz) that has an added digital printing step. Two main forms exist:

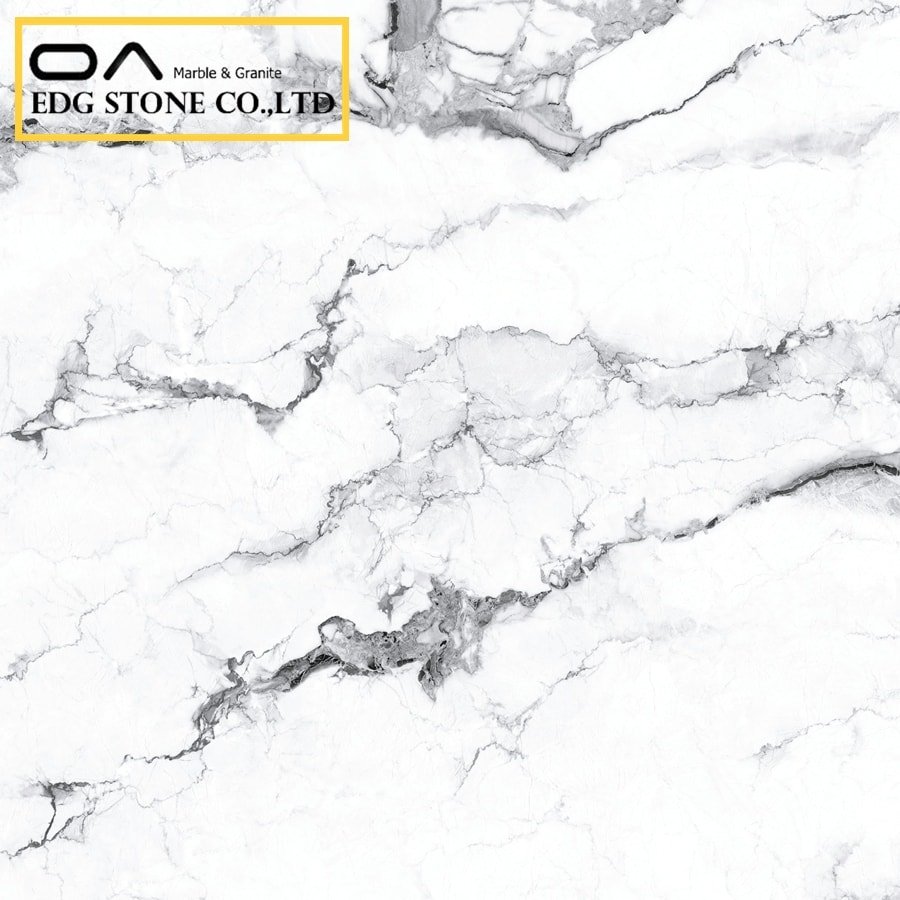

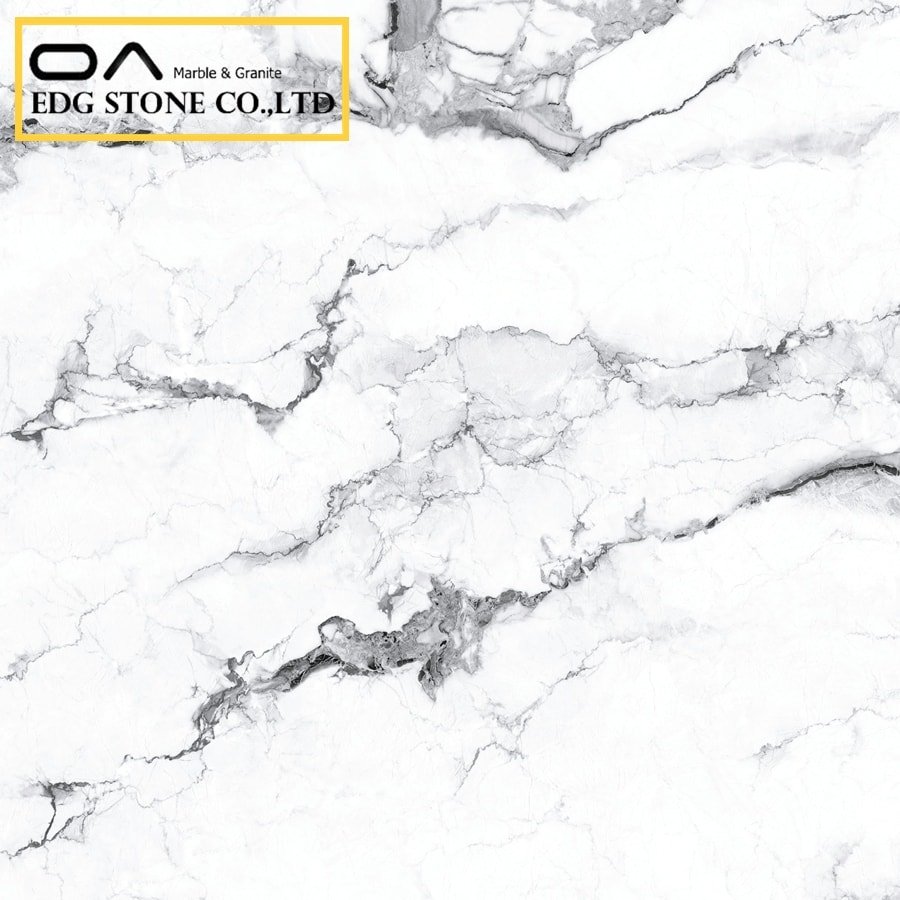

Surface / digital-print quartz: a high-resolution image is printed onto the slab face (UV or inkjet technology) to reproduce marble/granite looks.

Full-body / through-body printed quartz: printing or additive factory processes embed patterning through the slab thickness so edges and waterfall seams match the face.

Both keep the same engineered quartz composition (quartz + resin) but add manufacturing steps that change appearance and (often) cost. Brands are now marketing “digital-printed” collections, and some manufacturers (e.g., major suppliers adding high-definition inkjet tech) specifically highlight this as a premium capability.

Short answer: Is printed quartz cheaper?

No — printed quartz is usually not cheaper than a comparable plain engineered quartz slab. The printing step (surface or through-body) adds cost: equipment, inks, color matching, QA, and often tighter slab selection for bookmatching. Multiple supplier pages and industry summaries note printed quartz typically carries a slight premium vs. commodity quartz ranges. That said, printed quartz often remains cheaper than high-end natural marble or exotic stone alternatives that achieve similar looks.

Pricing context — typical quartz cost ranges (2024–2025 market snapshot)

To decide “cheap,” you need benchmarks:

Installed engineered quartz: industry price guides show typical ranges of roughly $50–$120 per ft² installed, depending on brand, finish, complexity, and region; low-end DIY/commodity offers can be lower, premium brands or complex installs are above the range. Use these as planning guides.

Printed quartz premium: suppliers and trade write-ups often describe printed/quasi-custom lines as “slightly more expensive” than standard quartz thanks to printing and extra QC. Expect a small premium (often 5–25%) over an equivalent non-printed engineered slab. Exact numbers depend on the supplier and pattern complexity.

Alternatives: Porcelain/sintered-stone/Neolith and premium sintered products can range comparably (about $55–$155/ft² installed, depending on brand and region). In some markets, porcelain or sintered stone may be cheaper than high-end printed quartz and outperform quartz on heat and UV resistance.

Why printed quartz costs more — the cost drivers

Printed quartz typically costs more because of several additional inputs and processes:

Printing hardware & inks: high-definition inkjet or UV printers designed for slabs are expensive; ink costs and maintenance add to unit cost.

Color management & QA: achieving photo-real, repeatable veining and bookmatching requires more manual inspection and stricter yield control.

Extra processing steps: lamination, topcoat matching, and sometimes special finishes (polished, honed, textured) increase labor and machine time.

Smaller runs & customization: bespoke patterns and low-volume custom prints can reduce economies of scale.

Full-body printing complexity: When a supplier guarantees edge continuity (full-body print), manufacturing is more complex than a surface ink job, and costs rise accordingly.

All these add up; the visual payoff is better realism and matching (important in high-end projects), but buyers pay for that extra control.

What looks like quartz but is cheaper?

If your main goal is a quartz-like aesthetic on a tight budget, consider alternatives:

Laminate (high-definition): modern high-definition laminates can mimic quartz or marble visuals at a fraction of the price. Durable for typical countertop tasks but less scratch-resistant.

Solid surface (e.g., Corian): mid-range, repairable, consistent color—often cheaper than premium quartz and variable by finish.

Porcelain / sintered stone (e.g., Neolith): can mimic stone, often comparable or slightly cheaper than premium quartz in some markets; porcelain is highly heat resistant and UV stable — good for indoor/outdoor use. Price overlaps with quartz and sometimes is cheaper on a per-m² basis depending on brand.

Buyer tip: evaluate long-term value, not just sticker price. Porcelain or sintered stone may have a higher upfront cost in some models but longer life or better heat resistance, making them more cost-effective in different use cases.

Is printed quartz cheaper than natural marble or granite?

Often yes. Printed quartz is specifically engineered to mimic marble’s look without marble’s porosity and maintenance. Because many printed quartz slabs copy marble aesthetics, they usually cost less than premium natural marbles and exotic granites. So, for a “marble look” with lower maintenance, printed quartz can be a cost-effective choice.

When printed quartz is worth the premium

Choose printed quartz when:

You need precise bookmatching across islands, waterfall edges, or large feature walls.

You want photo-real marble or designer patterns, but value quartz’s stain resistance and low maintenance.

The project is high-visibility (hotel lobby, restaurant bar) and visual continuity is mission-critical.

You want a specific, branded “look” not available in commodity quartz.

If your priorities are purely cost or extreme heat tolerance (e.g., commercial cookline), printed quartz may be overkill or not the right material. Consider porcelain/sintered stone or granite for high heat zones.

Procurement & RFQ checklist for printed quartz buyers

To get accurate price comparisons and avoid surprises, include these in your RFQ:

Explicitly state “printed quartz” and whether you mean surface-print or full-body / through-body print.

Slab size, thickness (20mm/30mm), and finish (polished/honed/leathered).

Bookmatch requirement: request slab IDs and full-slab photos for approval.

Edge profiling & miter tolerance (especially for waterfall edges).

Packaging & shipping terms (FOB/CIF), lead time, MOQ, and inspection rights.

Fabricator safety documentation (wet cutting, LEV, HEPA filtration) to confirm silica-control practices. Regulatory attention to silica is high—ask for compliance docs.

Maintenance & durability — printed vs non-printed quartz

Printed quartz inherits engineered quartz’s performance: non-porous, stain-resistant, and easy to clean. The printed surface is sealed during finishing; it does not require day-to-day maintenance. Heat sensitivity is shared: avoid placing hot pans directly on quartz surfaces — use trivets. Manufacturer care guides and warranties remain your best source for approved cleaners and procedures.

Regulation & safety — why this matters to buyers

Two regulatory trends affect procurement and supply risk:

Worker safety & silica enforcement (USA & elsewhere): OSHA and similar agencies have inspection and guidance programs addressing respirable crystalline silica from stone fabrication — buyers should insist fabricators follow wet cutting, local exhaust ventilation, and PPE protocols. Noncompliant suppliers create project risk.

Australia’s engineered stone ban & import controls: Australia introduced a domestic ban on engineered stone supply/use (effective July 1, 2024) and has moved to prohibit imports (from Jan 1, 2025). This regulatory action shows how fast policy can change and impact supply — international buyers or specifiers with projects in Australia must adjust sourcing plans.

Procurement action: require supplier compliance statements, third-party safety audit records where applicable, and confirm whether specific jurisdictions affect shipments or manufacture.

Quick cost examples & how to compare quotes

Ask suppliers to provide per-slab FOB and a full installed per-ft² quote (include fabrication, cutouts, sinks, edges). Many fabricators quote installed ranges (materials + labor) between $50–$120/ft² for quartz, so evaluate printed quartz quotes against that benchmark.

When comparing to porcelain or sintered slabs, request material + install pricing; some porcelain brands compete directly with upper-end quartz pricing and can be cheaper for equivalent looks.

FAQ — Google hot-search style (visible Q&A)

Q1: Is printed quartz more expensive than standard quartz?

A: Usually yes — printed quartz normally carries a small premium over commodity engineered quartz because of the printing and QA steps, but it’s often less expensive than high-end natural stones.

Q2: What is the difference between printed and non-printed quartz?

A: Both are engineered quartz (quartz + resin). Printed quartz adds digital printing (surface or through-body) to create photo-real patterns and better bookmatching; non-printed quartz uses factory patterns and pigments without high-definition printing.

Q3: What is the cheapest type of quartz?

A: “Cheapest” depends on brand and local supply. Economy or second-choice quartz (factory overstock colors or discontinued lines) is usually the least expensive. Commodity, widely available quartz colors cost less than premium or printed lines. Compare slab-level quotes.

Q4: What looks like quartz but is cheaper?

A: High-definition laminate, some solid surface brands, and in many markets, porcelain / sintered stone can mimic quartz or marble at competitive prices. Balance upfront cost against durability and heat/UV performance.

Q5: Is printed quartz worth the extra money?

A: If you need precise matching, bookmatching, waterfall edges, or a designer stone look without marble maintenance, printed quartz can be worth the premium. For budget projects, commodity quartz or porcelain may be a better value.

Semantic Closure — How / Why / What / Options / Considerations

How: Printed quartz is produced by adding digital printing (surface inkjet or factory through-body printing) to engineered quartz manufacturing; this creates photoreal patterns and enables bookmatching. Request full-slab photos and slab IDs when procuring.

Why: The premium pays for design control, bookmatching, and reduced seams across waterfall edges—valuable in high-end residential and hospitality projects.

What: Printed quartz usually costs a modest premium vs standard quartz but remains an economical route to marble-like visuals compared with real marble. Ask suppliers for slab-level FOB and installed quotes.

Options: For heat-heavy zones or outdoor use, consider porcelain/sintered stone; for strict budgets, high-definition laminate or commodity quartz are cheaper options.

Considerations: Factor in fabrication complexity, silica-safety documentation (wet cutting and LEV), slab reservation for matched runs, and warranty constraints. Regulatory changes (e.g., engineered stone bans/import controls in some markets) can suddenly affect supply—confirm market access before large orders.

Focus keyword + 50 SEO tags

Focus keyword: is printed quartz cheaper

50 SEO tags (purchase-intent + long-tail):

is printed quartz cheaper, printed quartz price, printed quartz vs quartz cost, is printed quartz more expensive than quartz, printed quartz slab cost, printed quartz countertops price, digital print quartz slab price, full body printed quartz price, printed quartz manufacturer, printed quartz factory wholesale, printed quartz FOB price, buy printed quartz slabs, printed quartz vs natural stone price, cheapest quartz types, cheapest quartz countertop, what looks like quartz but cheaper, porcelain vs quartz price, sintered stone vs quartz cost, quartz vs porcelain cost comparison, cheap quartz alternatives laminate, Corian vs quartz price, printed quartz bookmatch cost, printed quartz lead time, printed quartz slab sizes, printed quartz 20mm 30mm price, printed quartz installation cost, printed marble look quartz price, printed quartz premium markup, printed quartz supplier China, printed quartz wholesale supplier, printed quartz sample request, printed quartz warranty, digital print quartz collection MSI Q+, printed quartz industrial printing, printed quartz edge match, printed quartz backlit panels, cost to install printed quartz island, printed quartz vs quartzite price, sintered stone cheaper than quartz, porcelain slab manufacturer price, granite vs printed quartz cost, engineered quartz ban Australia, silica safety fabricator documentation, printed quartz slab photos, printed quartz vs engineered stone, printed quartz maintenance, printed quartz heat resistance, printed quartz finishes, printed quartz customization cost.