Explore Edgstone's Premium Limestone Collection

Discover unparalleled elegance with EDG Stone’s Premium Limestone Collection, meticulously crafted in our advanced Marble Factory. As a leading Marble Supplier and Manufacturer, we source high‑grade limestone blocks renowned for subtle veining and warm neutral hues. Each slab and tile undergoes rigorous quality checks before being precision‑cut by our in‑house Marble Fabricator team. Whether you’re a Marble Wholesaler seeking consistent inventory or a designer specifying bespoke installations, EDG Stone delivers uniform thickness and tailored edge profiles. Our limestone’s natural texture adds depth to flooring, wall cladding, and countertops, ensuring a timeless aesthetic. Request samples today to experience the unmatched quality and versatility of EDG Stone limestone.

- Home

- >

- Limestone

Natural Limestone Slabs & Tiles Manufacturer in China

As a premier Limestone Manufacturer in China, EDG Stone specializes in producing natural limestone slabs and tiles that meet global standards. Our Marble Factory combines modern CNC technology with traditional craftsmanship to deliver precise cuts, consistent finishes, and minimal variation across batches. Partnering with top Limestone Suppliers, we source raw blocks from trusted quarries, ensuring superior color uniformity and minimal fissures. Our Marble Fabricator team offers custom edge treatments—bevel, bullnose, or chamfer—to suit diverse architectural needs. Marble Wholesaler clients benefit from competitive factory‑direct pricing and efficient logistics. Choose EDG Stone for reliable lead times, comprehensive technical support, and environmentally responsible production practices.

Detailed Specification

| Property | Value / Range | Units | Notes |

|---|---|---|---|

| Composition | ≥95% calcite | % by weight | Primary mineral |

| Mohs Hardness | 3–4 | Mohs | Moderate scratch resistance |

| Density | 2.5–2.7 | g/cm³ | Lightweight for ease of installation |

| Water Absorption | 0.2–1.0 | % | Requires periodic sealing |

| Compressive Strength | 70–100 | MPa | Adequate for countertops & cladding |

| Thermal Conductivity | 1.5–2.5 | W/m·K | Retains warmth, ideal for hearths |

| Typical Uses | Countertops, flooring, and cladding | — | Versatile architectural stone |

| Maintenance | Reseal every 6–12 months | months | Prevents staining & etching |

Discover Our High-End Limestone Countertops & Slabs Collection

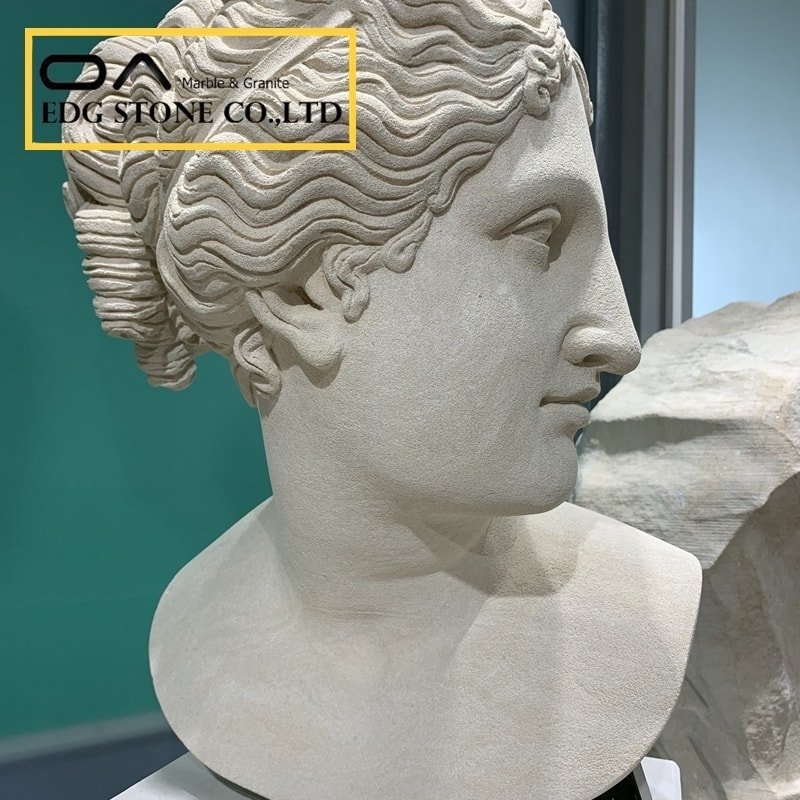

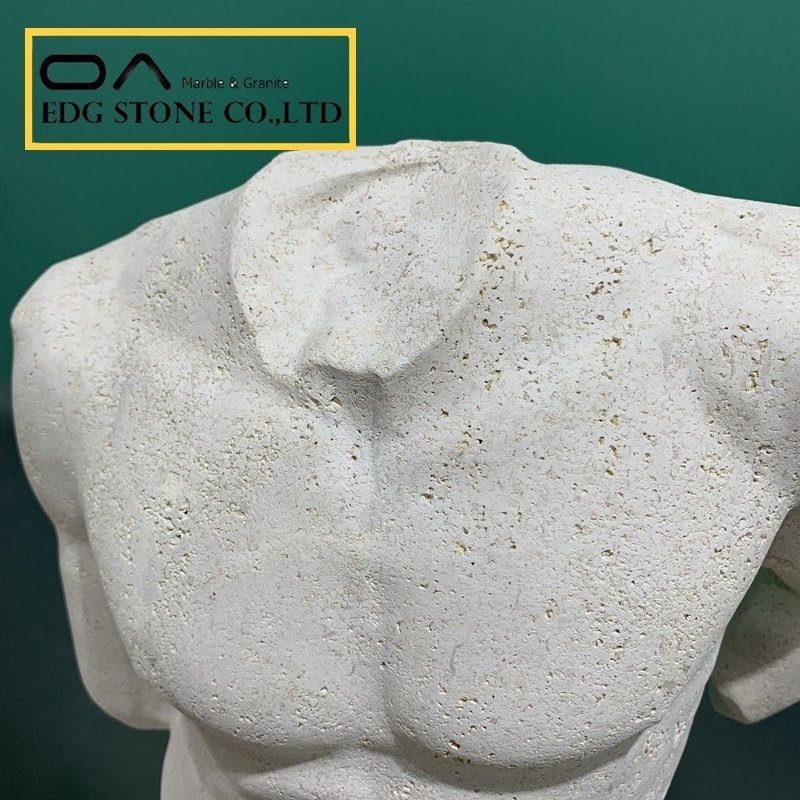

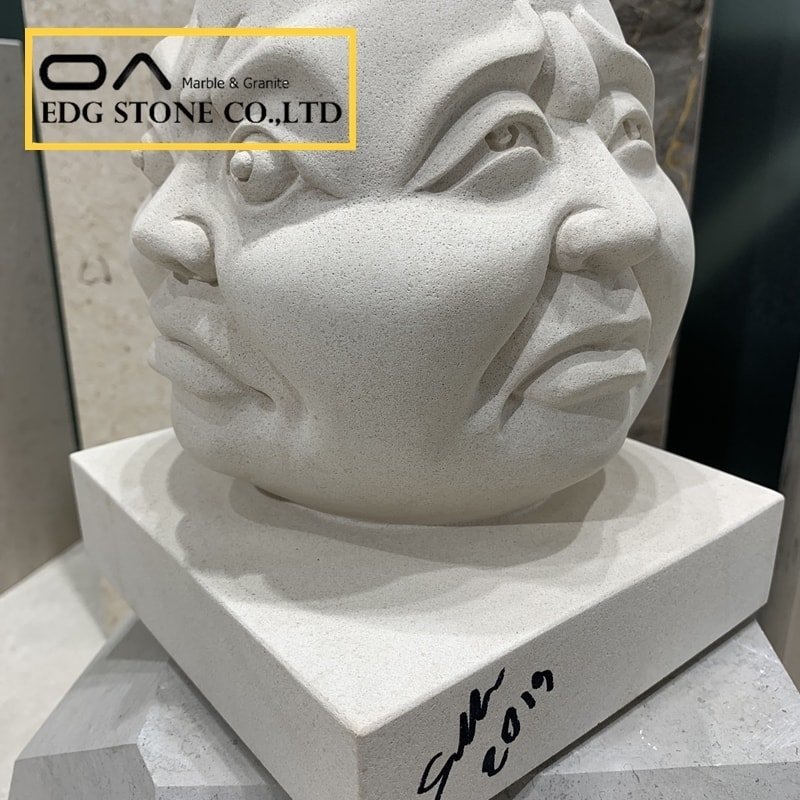

Our Star Limestone Furniture Series

Our Star Limestone Product Series

Why EDG Stone Limestone Slabs & Countertops? - Factory Direct Limestone Countertops & Slabs Buy

Choosing limestone from EDG Stone means you’re partnering with a true Limestone Manufacturer and Limestone Supplier that controls every step—from block selection in our state‑of‑the‑art Marble Factory to precision cutting and finishing by our in‑house Limestone Fabricator team. Factory‑direct pricing through our Limestone Wholesaler network eliminates middleman markups, giving you competitive rates without sacrificing quality. Each slab undergoes rigorous inspection for color consistency, minimal fissures, and optimal density, ensuring durability in both residential and commercial applications. We offer custom edge profiles, a variety of honed, brushed, or flamed finishes, and fully documented technical data sheets. With EDG Stone’s sustainable quarry partnerships and expert project support, your limestone installation will be as beautiful as it is long‑lasting.

Limestone Countertops & Tables

What are Limestone Countertops?

Limestone countertops are durable stone surfaces crafted from sedimentary rock known for its fine grain and muted color palette. EDG Stone’s Marble Supplier network sources premium limestone blocks, which our Marble Factory transforms into slabs and tiles.

Limestone Slab Applications

As a Marble Manufacturer and Fabricator, we cut countertops to size, offering custom edge profiles like ogee or eased. Limestone’s versatile applications include kitchen islands, bathroom vanities, bar tops, and outdoor patios. Its porous nature provides a matte, tactile finish ideal for rustic, Mediterranean, or contemporary designs. EDG Stone’s Marble Wholesaler services ensure you receive consistent slab thickness and timely delivery, making limestone a practical and stylish choice for residential and commercial spaces.

Limestone Slab Applications

Limestone Slab Advantages

Limestone Slab Advantages

Limestone slabs offer a natural, matte aesthetic with warm neutral tones that complement diverse design styles. EDG Stone’s Marble Factory ensures each slab has minimal variation, making large installations visually cohesive. As a Marble Supplier and Manufacturer, we provide honed, brushed, or flamed finishes that enhance slip resistance for flooring and outdoor use. Limestone’s moderate hardness resists wear in high‑traffic areas while remaining easy to machine for intricate edge profiles. Our Marble Fabricator team excels at precision cutting and seam matching, delivering seamless countertops and cladding. Additionally, limestone’s eco‑friendly credentials—natural origin and recyclability—align with sustainable building practices promoted by EDG Stone’s Marble Wholesaler partners.

Limestone Slab Disadvantages

Despite its beauty, limestone is softer than granite and can scratch or etch under heavy use. EDG Stone, as a responsible Marble Manufacturer, advises sealing every 6–12 months to prevent staining and water absorption. Acidic spills—wine, citrus—should be wiped immediately, as limestone’s calcite composition is prone to mild etching. Our Marble Fabricator teams recommend honed or brushed finishes to minimize visible wear patterns. In commercial settings, additional maintenance costs for periodic resealing may arise. Marble Wholesaler clients should consider traffic levels before specifying limestone. EDG Stone’s technical support helps clients assess suitability and develop maintenance plans that preserve limestone’s timeless appeal.

Limestone Slab Disadvantages

Limestone Slabs Design

Limestone Slabs Design

Limestone slabs bring understated elegance with neutral gray, beige, and cream hues, making them ideal for minimalist and classic interiors. EDG Stone’s Marble Factory offers book‑matched panels to highlight linear veining across walls or flooring. As a Marble Supplier and Manufacturer, we provide custom sizes up to 120″×60″, allowing expansive, seamless installations. Our Marble Fabricator team crafts precise edge details—waterfall edges for islands, bullnose for showers—that accentuate design intent. Limestone pairs beautifully with wood, metal accents, and glass, fostering harmonious material palettes. Marble Wholesaler customers appreciate our ability to deliver coordinated tile sets and decorative inlays, ensuring cohesive design schemes across multiple surfaces and applications.

Limestone Slabs Maintenance

Proper care ensures limestone’s longevity and beauty. EDG Stone, as a leading Marble Supplier, recommends routine cleaning with pH‑neutral stone cleaners and a soft cloth to avoid scratches. Our Marble Manufacturer guidelines call for sealing every 6–12 months, performed by local Marble Fabricator professionals or skilled maintenance teams. Spills should be blotted immediately, preventing oils and acids from penetrating the surface. For deep cleaning, a mild non‑abrasive soap diluted in water and a soft brush effectively remove dirt without dulling the finish. Marble Wholesaler partners receive detailed maintenance manuals with product orders, ensuring clients have the knowledge to preserve their limestone investments for years to come.

Limestone Slabs Maintenance

Why choose limestone from Edgstone?

Choosing limestone from EDG Stone means you’re partnering with a true Limestone Manufacturer and Limestone Supplier that controls every step—from block selection in our state‑of‑the‑art Marble Factory to precision cutting and finishing by our in‑house Limestone Fabricator team. Factory‑direct pricing through our Limestone Wholesaler network eliminates middleman markups, giving you competitive rates without sacrificing quality. Each slab undergoes rigorous inspection for color consistency, minimal fissures, and optimal density, ensuring durability in both residential and commercial applications. We offer custom edge profiles, a variety of honed, brushed, or flamed finishes, and fully documented technical data sheets. With EDG Stone’s sustainable quarry partnerships and expert project support, your limestone installation will be as beautiful as it is long‑lasting.

RFQ – About Limestone Countertops, Slabs, Tiles

Selection

Q: What factors should I consider when selecting limestone slabs or tiles?

A: Evaluate color uniformity (white, beige, gray), veining patterns, slab thickness (1–3 cm), finish options (honed, brushed, tumbled), and check for fissures or pitting. Request full‑slab photos and samples from your limestone supplier to confirm consistency.Q: What is the difference between honed and polished limestone finishes?

A: Honed limestone has a matte, non‑reflective surface ideal for slip resistance, while polished limestone offers a glossy sheen that highlights color and veining but may show scratches more easily.Q: How do I choose the right limestone grade for indoor vs. outdoor use?

A: For interiors, select fine‑grain, high‑density grades with low porosity; for exteriors, choose denser, frost‑resistant varieties with textured finishes (e.g., flamed or brushed) to improve traction.Q: Are large‑format limestone slabs suitable for waterfall countertops?

A: Yes—limestone slabs up to 120″×60″ can be book‑matched and edge‑profiled for waterfall islands, but ensure adequate structural support and professional fabrication for safe overhangs.

Cost

Q: How much do limestone slabs typically cost per square foot?

A: Basic domestic limestones start at $30–$50 /ft² installed; premium imported or exotic varieties range $60–$100 /ft². Custom finishes and edge profiles add $5–$15 /ft².Q: What additional expenses should I budget beyond material cost?

A: Include fabrication (cutting & edging, $10–$20/ft²), delivery ($0.50–$2/ft²), installation labor ($8–$15/ft²), sealing, and 10–15% waste allowance.Q: Do limestone tiles cost less than slabs?

A: Yes—limestone tiles typically cost $5–$15 /ft², but require more grout and labor; large slabs reduce seam count but have higher material and handling fees.Q: How can I secure the best wholesale pricing on limestone?

A: Order in bulk (≥500 ft²), choose common grades, negotiate a combined quote for material + fabrication + installation, and work directly with quarries or factory‑direct suppliers.

Maintenance

Q: How often should limestone slabs and tiles be sealed?

A: High‑traffic areas (floors, countertops) require sealing every 6 months; low‑traffic walls and backsplashes can be sealed annually. Test by spilling water—if it darkens, reseal.Q: What is the best cleaner for daily limestone maintenance?

A: Use a pH‑neutral stone cleaner or mild dish soap diluted in water. Avoid acidic or abrasive cleaners that can etch or dull the surface.Q: How do I remove oil stains from limestone?

A: Apply a baking‑soda poultice (mix baking soda and water), cover for 24 hours, then gently scrape and rinse. For organic stains, use a hydrogen peroxide–based poultice.Q: Can I use vinegar or bleach on limestone?

A: No—acids (vinegar) etch limestone, and bleach can weaken the stone. Stick to stone‑safe, pH‑neutral products.

Comparison

Q: Limestone vs. marble: which is more porous?

A: Limestone (0.2–1.0% absorption) is slightly more porous than most marbles (0.1–0.4%), requiring more frequent sealing to prevent stains.Q: Limestone vs. travertine: Which is better for outdoor flooring?

A: Travertine often has more voids and can be prone to chipping; dense, honed limestone offers better durability and slip resistance in exterior applications.Q: Honed limestone vs. polished porcelain tile: which offers better slip resistance?

A: Honed limestone has natural micro‑texture for traction, while polished porcelain can be slippery when wet. Choose textured porcelain if you need a high‑gloss look with grip.Q: Limestone slabs vs. engineered stone countertops: Which is more heat resistant?

A: Natural limestone withstands moderate heat but can etch under acids, whereas engineered quartz resists stains but may discolor at very high temperatures.

Localization

Q: Where can I find limestone slab suppliers near me?

A: Search “[your city] limestone slab supplier” or check local stone yards. National chains and factory‑direct quarries often maintain regional warehouses with ready stock.Q: Do I need a permit to install limestone countertops?

A: Typically, no for countertop replacement; structural modifications (heavy waterfall islands) may require building permits—verify with local authorities.Q: How do I select the best limestone fabricator in my region?

A: Look for Natural Stone Institute certification, review portfolios for seam quality, request references, and compare quotes from multiple fabricators.Q: Are there import restrictions on certain limestone varieties?

A: Rare or protected quarry stones may need CITES permits. Most commercial limestone types are freely importable—confirm with your supplier if sourcing exotic grades.